ESS EV Pouch Cell PACK Automatic Assembly Line China

Other recommendations

Overview

Semi-automatic PACK line Pouch Cells

The pouch battery PACK line is an automated production line that assembles components such as pouch battery cells and protection boards into a complete battery pack, and then conducts a series of processes including inspection, testing, and packaging. The following is a detailed introduction to the pouch battery PACK line:

Main process

Cell feeding and inspection: Place the cells on the conveyor belt, read the cell information through the scanning station, and simultaneously test the voltage, internal resistance, etc. of the cells. Screen out the qualified cells to enter the next process, and the unqualified ones are placed in the NG channel through the NG discharge module.

Tab processing: It includes processes such as tab cutting, flattening, and bending. Tab cutting is to trim the tab to an appropriate length; the flattening process is used to eliminate the deformation or wrinkles generated by the tab during the production process; bending is to bend the tab according to the design requirements for subsequent welding and assembly.

Tape - sticking process: Stick various tapes, such as groove tape and tab tape, on the battery cell or tabs, which play roles in insulation, fixation, and protection.

PCM Assembly and Welding: Assemble the protection board (PCM) with the battery cells and achieve electrical connection through the welding process to ensure the safety performance and charge-discharge management function of the battery pack.

Cell Stacking and Module Assembly: According to the design requirements of the battery pack, stack multiple cells and assemble them into a battery module. At the same time, install components such as busbars and insulating materials in the module.

Laser welding: The laser welding technology is used to weld the tabs and busbars, modules and casings, etc., to ensure the reliability and electrical conductivity of the connections. During the welding process, a visual positioning system and a smoke and dust purification and recovery treatment system are usually equipped.

Inspection and Testing: It includes appearance inspection, dimensional inspection, Hi-pot test, insulation test, functional test, etc., to ensure that the appearance quality, dimensional accuracy, electrical performance, etc. of the battery pack meet the standard requirements.

Packaging process: Package the battery packs that have passed assembly and inspection, such as applying heat - shrinkable film, affixing labels, etc., to protect the battery packs from damage during transportation and storage.

Device composition

Conveying equipment: such as multi-speed chains, belt lines, etc., is used to convey battery cells, modules, etc. between various workstations to ensure the continuity of production.

Robotic arms and robots: They can perform operations such as material handling and assembly, improving production efficiency and accuracy while reducing human intervention.

Welding equipment: such as ultrasonic welding machines, laser welding machines, etc., is used in processes such as tab welding and module welding.

Testing Equipment: It includes voltage and internal resistance testers, X-ray inspection equipment, CCD inspection equipment, Hi-pot testers, etc., and conducts various performance tests and quality monitoring on battery cells, modules, and battery packs.

Gluing Equipment: Automatically completes the gluing process to ensure the position accuracy and quality of tape pasting.

Heat Shrink Packaging Equipment: Used for heat shrink film packaging of battery packs to make the packaging tight, beautiful, and protective.

Technical Features High Degree of Automation: Adopts advanced automation technologies such as robotic arms, sensors, and control systems to achieve fully automated production from battery cell loading to finished product packaging, greatly improving production efficiency and reducing labor costs.

High Precision and Consistency: Through precise process control and equipment adjustment, it ensures that the assembly quality and performance parameters of each battery pack are highly consistent, improving the reliability and stability of the product.

Flexible Production: Adopts a modular design of functional units, enabling rapid switching of the production of different specifications and types of soft-pack batteries to meet the market's demand for diversified products and support the customized production of enterprises.

Intelligent Management: Equipped with a full-closed loop production control of the MES system, it monitors various indicators of the production line in real-time, realizes the traceability and intelligent management of the production process, facilitates the timely discovery and resolution of production problems, and improves production efficiency and product quality.

Application Fields Consumer Electronics Field: Widely used in various consumer electronic products such as smartphones, tablets, laptops, smartwatches, TWS earphones, etc., providing high-performance and high-energy-density battery packs for them.

Power Battery Field: In new energy vehicles such as electric vehicles, electric motorcycles, and electric bicycles, the battery packs produced by the soft-pack battery PACK line have advantages such as high energy density and malleable shape, which can better meet the vehicle's space layout and performance requirements. Energy Storage Field: Used in energy storage systems such as solar energy storage, wind energy storage, and grid energy storage. Multiple soft-pack batteries are assembled into large-capacity battery packs to achieve the storage and release of electrical energy, improving energy utilization efficiency and stability.

※ Equipment function

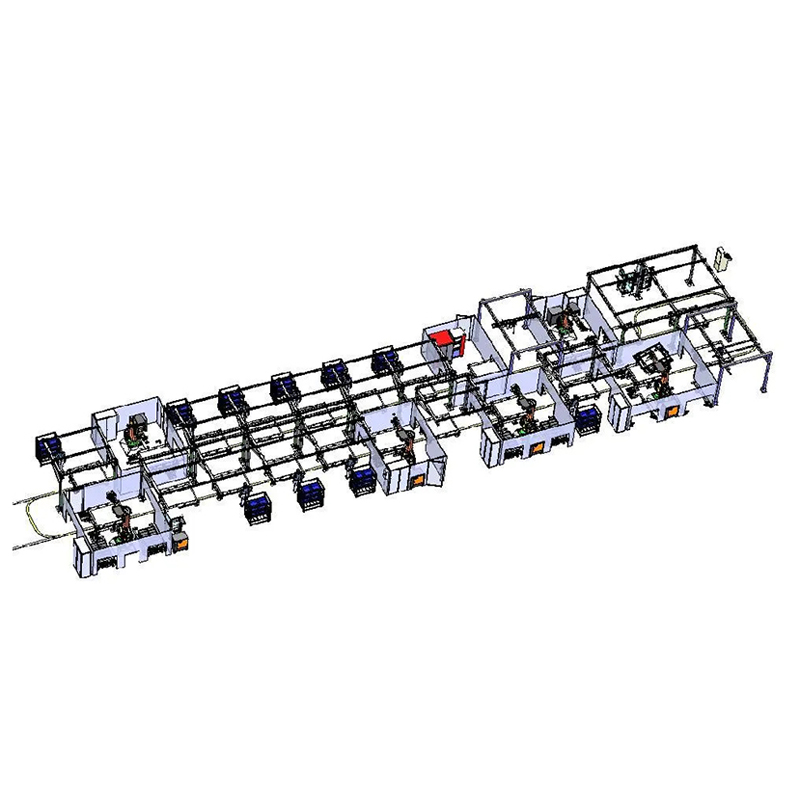

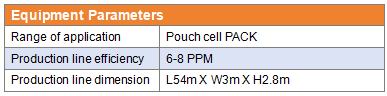

This customized production line is mainly used for the grouping, welding, testing, and assembly of lithium battery pouch cell modules PACK for outdoor ess, scooter and electric tricycles.The line includes: manual cells loading/automatic cells code scanning/OCV testing/TAB leveling/TAB cutting/cutting & flattening/polarity flipping/manual gluing/manual stacking/manual trapping/manual installation BUSBAR/TAB bending/TAB flattening/laser welding/total internal voltage internal resistance testing/gantry lifting and transfer production line/PACK manual assembly/PACK lifting and offline.

Equipment advantage

█ High efficiency

Main workstations of the equipment are automated,improve production efficiency

█ Compatibility

Compatible with multiple models of unilateral tab pouch cells PACK

█ Modularization

Modular layout, convenient to maintain equipment, free combination of processes, and flexible operation

- Tel:

-

Email:

Certifications

INQUIRY