Cylindrical Battery Cell PACK Semi-automatic Assembly Line

Other recommendations

Overview

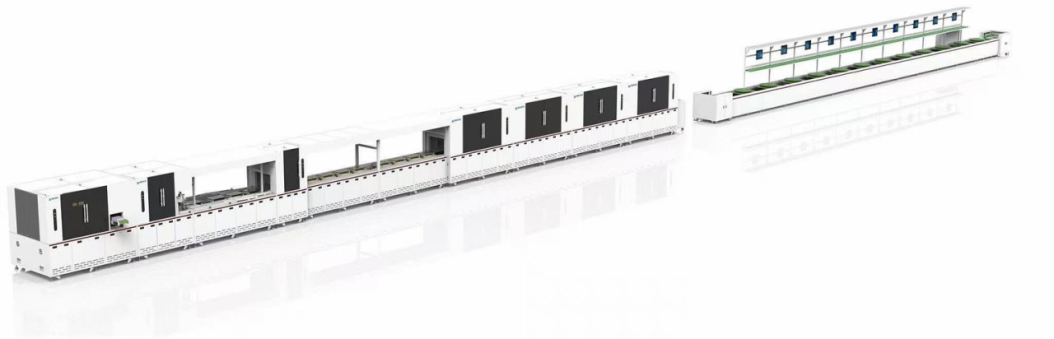

Automatic Production Line for Cylindrical Battery PACK

An automatic production line for cylindrical battery PACK refers to a fully automated production system that assembles cylindrical battery cells (such as 18650, 21700, etc.) into battery packs (PACK) using automated equipment and systems.Its core is to realize the automated processing from individual cells to finished battery packs through mechanical, electrical control, and robotic technologies, reducing manual intervention and improving production efficiency, consistency, and safety.

The core of a cylindrical battery PACK is to combine a large number of cylindrical cells in series/parallel, together with components such as a protection board (BMS), casing, and wiring harnesses, to form a battery pack with stable charging and discharging capabilities (used in scenarios such as new energy vehicles, energy storage equipment, and consumer electronics). A typical process of an automatic production line includes:

1. Cell Loading and Inspection

Cylindrical cells are transported from the silo to the production line via automated loading equipment (e.g., vibratory bowls, robotic gripping). Simultaneously, unqualified cells are rejected through visual inspection (for appearance defects, dimensional deviations) and electrical testing (voltage, internal resistance) to ensure the consistency of raw materials.

2. Cell Sorting and Matching

Qualified cells are automatically arranged (e.g., neatly arranged into a matrix) according to a preset quantity (meeting series/parallel requirements). They are then "sorted and grouped" based on parameters such as voltage and internal resistance (to ensure performance matching of cells in the same battery pack and reduce cycle differences).

3. Cell Fixing and Welding

Arranged cells are fixed by brackets, adhesives, or fixtures (to prevent shaking). Subsequently, automated welding equipment (e.g., laser welding, ultrasonic welding) welds cell tabs to busbars (conductive components connecting cells) to form modules (small battery groups). Welding quality (e.g., cold solder joints, missing welds) is inspected simultaneously during the welding process.

4. Module/Cell Integration and Assembly

Multiple modules or cell groups are transferred to the final assembly station by automated robots, where they are assembled with components such as protection boards (BMS), casings, and wiring harnesses to complete the structural integration of the battery pack.

5. Encapsulation and Testing

The assembled battery pack undergoes housing sealing (e.g., laser welding capping, screw fastening). It is then subjected to full-item testing by automated equipment, including total voltage, capacity, insulation performance, charge-discharge cycles, and short-circuit protection, to ensure performance compliance.

6. Data Traceability and Logistics

The production line records full-process data (e.g., cell ID, welding parameters, test results) through an MES (Manufacturing Execution System) to enable quality traceability. Qualified finished products are transported to the warehousing area via automated logistics equipment (e.g., AGVs).

Key Features

●Fully automated integration:

The entire process from cells to finished battery packs requires no manual operation, with continuous production achieved through robots, conveyors, visual inspection, and other equipment.

●High consistency:

Precise control by automated equipment (e.g., welding pressure, sorting accuracy) reduces errors caused by manual operations, ensuring uniform battery pack performance.

●High efficiency and scalability:

A single production line can process thousands to tens of thousands of cells per hour, meeting the large-scale production needs of new energy vehicles, energy storage, and other fields.

●Safety:

Automated equipment isolates high-risk processes such as cell welding and high-voltage testing, reducing the risk of manual exposure. Meanwhile, real-time detection systems can quickly reject abnormal cells to avoid safety hazards.

Application Scenarios

It is mainly used in new energy vehicles (e.g., Tesla's 4680 cylindrical battery packs), energy storage stations, power tools, smart home devices, and other fields, especially in scenarios requiring high consistency and large-scale production of battery packs. Its automation capability is a key support for the industrial mass production of cylindrical batteries in large-size, high-energy-density applications.

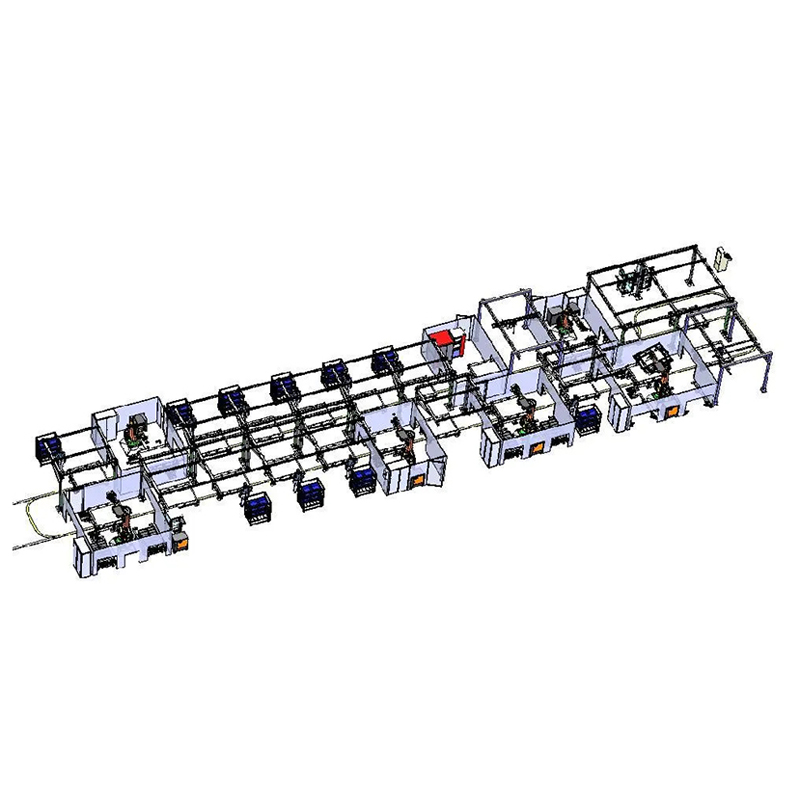

This line is used for semi-automatic production of cylindrical lithium battery module PACK. The whole line includes: whole box battery cell feeding/automatic cells picking/automatic pasting of barley paper/automatic scanning of codes/battery cell sorting/secondary scanning and grouping/cells in holder & nickel strip placement/CCD polarity detection/manual installation of fixtures/front spot welding/module flipping/back spot welding/module flipping/PACK assembly and testing and other processes.

- Tel:

-

Email:

Certifications

INQUIRY