I/C ESS LFP Prismatic Battery PACK Full-Automatic Assembling Line

Other recommendations

Overview

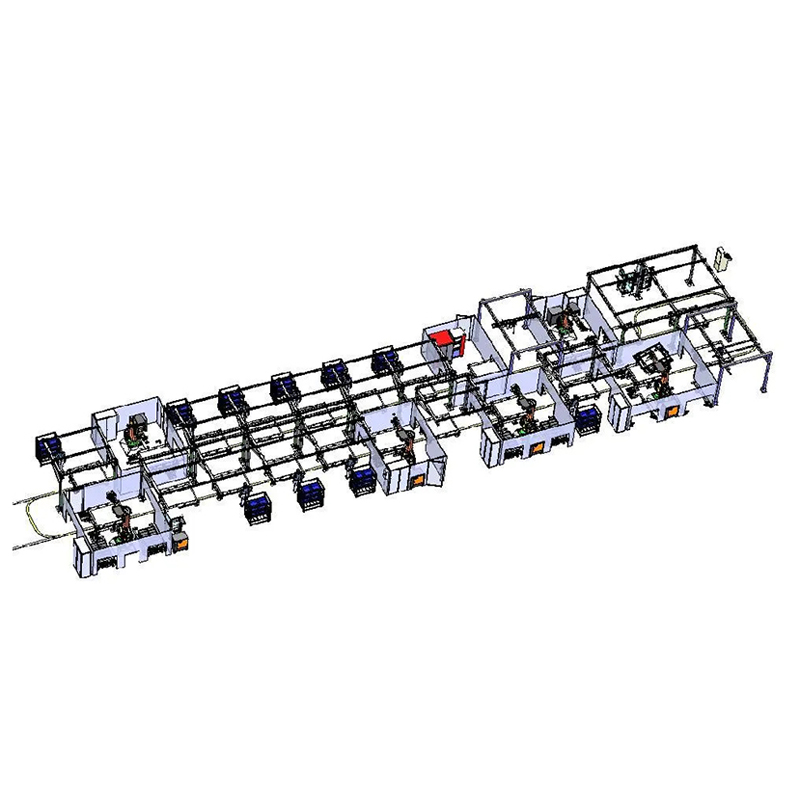

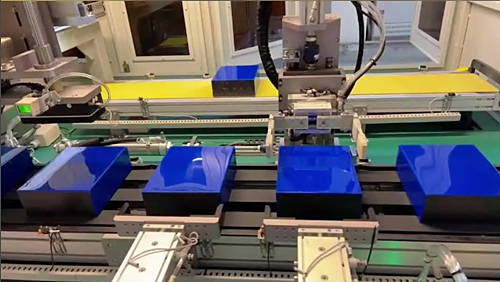

I/C ESS LFP PRISMATIC BATTERY PACK AUOMATIC ASSEMBLY LINE

Equipment function

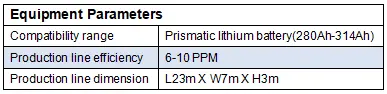

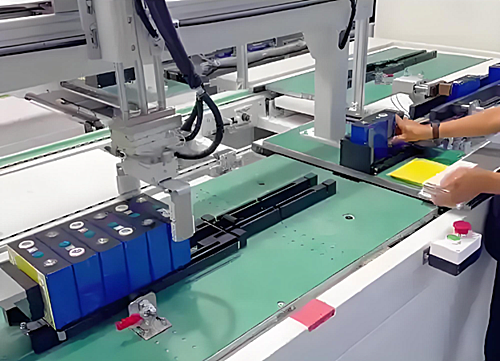

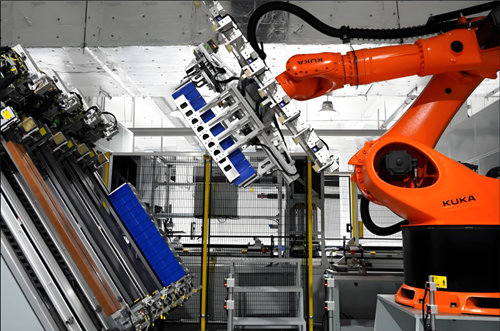

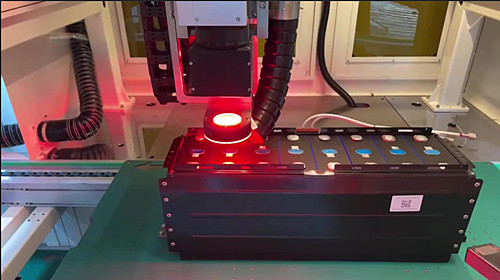

This customized production line is mainly used to achieve the assembly, welding, testing, and assembly functions of I/C ESS PACK.The assembly line includes: robot cell loading/code scanning/OCV sorting/NG discharge and replenishment/cell production line transfer/polarity detection/flipping/automatic gluing/automatic stacking (5 * 2 stacking tower)/automatic extrusion & manual steel strip binding/polarity detection&polarity addressing/pole cleaning/manual installation of CSS/robot laser welding/module testing/module transfer production line/liquid cooling box online/liquid cooling box gluing/module in PACK box/PACK assembly and testing/PACK lifting offline, etc.

Equipment advantage

█ High efficiency

High-efficiency production, with an efficiency of up to 18PPM

█ Automation

The main workstations all adopt automated processing, efficient and saves labor cost

█ Traceability

The MES system can upload data in real-time and accurately trace each product

Main workstation :

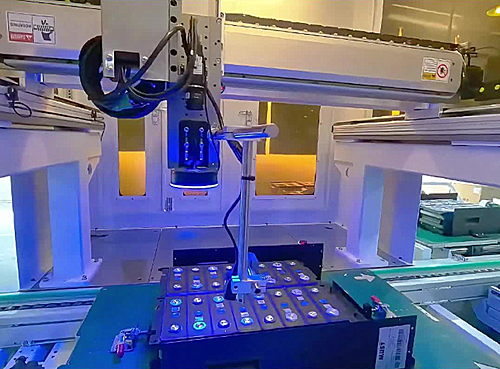

1.Robot automatic cells loading online and stacking.

2.Cells OCV / IR sorting,Code scanning,NG cells discharge,cells replenishment

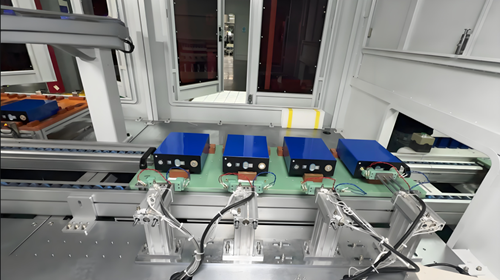

3.Cell transfer on production line

4.Cells CCD polarity/anode cathode detection and confirmed

5.Cells polarity/anode cathode flipping and matching

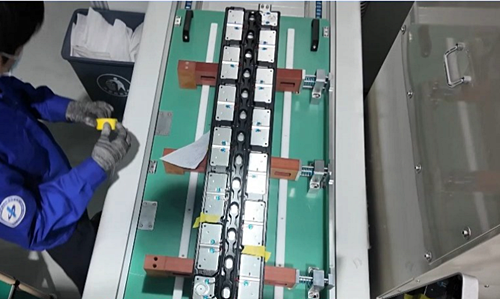

6.Manual cells surface adhesive tape pasting

7.Automatic cells stacking

8.Module extrusion/steel tape circle placement and binding

9.Polarity detection/anode cathode pole addressing

10.Anode cathode electrode pole laser cleaning

11.CCS manual placement

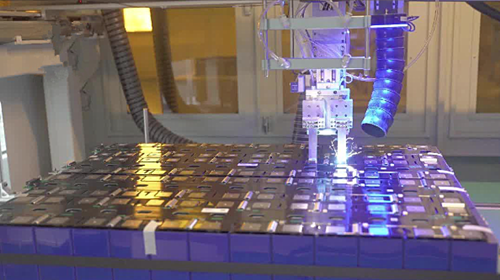

12.CCS robot laser welding

PACK assembly manufacture workstation optional manual/automatic.

- Tel:

-

Email:

Certifications

INQUIRY