ESS Energy Storage Lithium Battery Pack Line LFP Prismatic Cell Semi-automatic Production Solutions

Other recommendations

Overview

ESS LFP PACK-RESIDENTIAL SEMI- AUTOMATIC PACK LINE(PRISMATIC CELLS)

The energy storage PACK production line is a core manufacturing process that integrates individual cells into battery packs with practical energy storage application functions. It focuses on controlling safety, consistency, and reliability, with the overall process being closely linked and having strict technical requirements, mainly including the following key links:

Cell Pretreatment and Screening

The initial stage of the production line is cell pretreatment, which involves conducting outlook inspection on incoming individual cells to eliminate those with defects such as damage and bulging. Subsequently, OCV/IR sorter (Open Circuit Voltage/Internal Resistance Sorting Equipment) is used to accurately detect parameters such as cell voltage and internal resistance. Cells with consistent performance are classified into the same batch according to preset standards, laying the foundation for subsequent series-parallel combination and minimizing the overall performance attenuation of the PACK caused by cell differences.

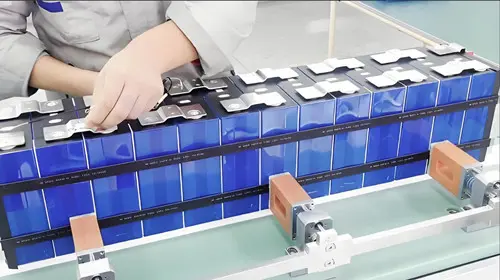

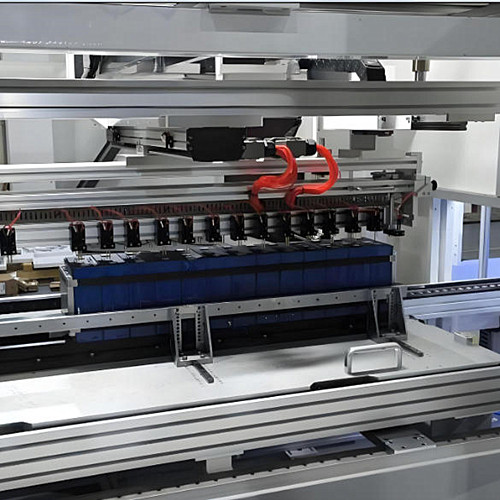

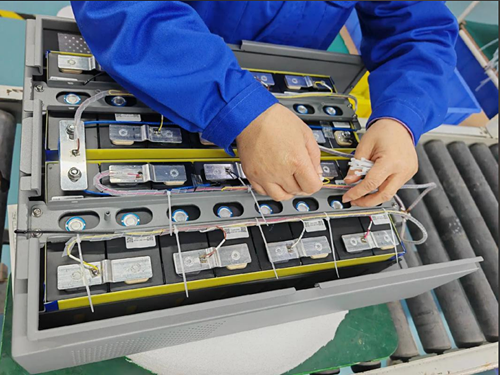

Cell Assembly and Connection

The screened cells enter the assembly process and are arranged in an orderly manner according to the design specifications of the battery pack to form cell modules. The core connection process adopts Aluminum busbar laser spot welding technology, which uses high-energy lasers to accurately weld the cell tabs to the aluminum busbars, ensuring that the welds are firm, have low resistance, and excellent thermal stability, avoiding problems such as cold welding and over-welding that may occur with traditional welding methods. Some production lines are also equipped with BFGS equipment (Battery Cell Grouping and Grasping Equipment) to realize automatic arrangement and grasping of cells, improving assembly efficiency and accuracy.

Module and PACK Integration

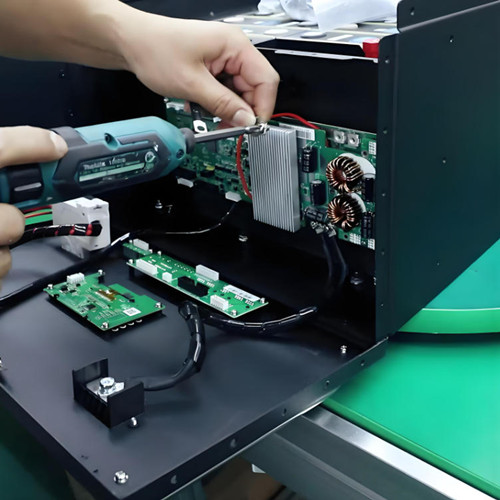

After the cell modules are assembled, they enter the PACK integration stage. Multiple modules are connected in series and parallel according to the circuit design, and core components such as the Battery Management System (BMS), high-voltage wiring harnesses, and low-voltage wiring harnesses are connected, and the outer shell is installed to form a complete battery pack structure. In this link, it is necessary to strictly control the connection sequence and fastening force of each component to ensure smooth circuits and stable mechanical structure.

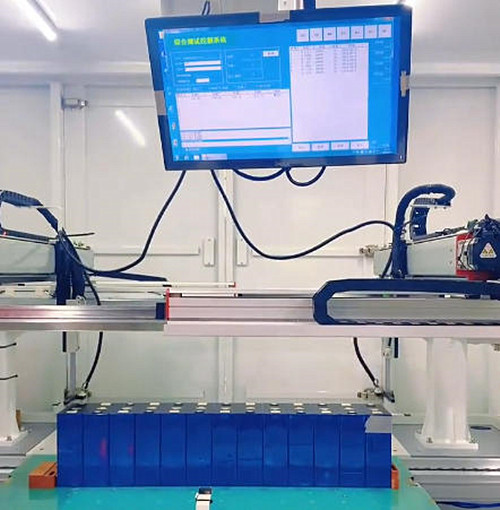

Performance Testing and Aging Verification

The integrated battery packs need to undergo multiple rounds of strict testing:

EOL testing (End-of-Line Testing): Comprehensive detection of basic parameters such as battery pack voltage, current, and insulation performance to eliminate circuit faults;

PACK charge-discharge performance testing: Simulating actual usage scenarios to test core indicators such as battery pack capacity, charge-discharge efficiency, and cycle performance;

PACK aging equipments: Screening out battery packs with early attenuation through long-term charge-discharge cycle aging tests to ensure the stability of products during long-term use.

At the same time, welded inspection runs through the connection link. Through methods such as visual inspection or ultrasonic flaw detection, it is ensured that the quality of laser welds meets safety standards, avoiding risks such as heat generation and short circuits caused by welding defects.

Finished Product Packaging and Traceability

Battery packs that pass all tests undergo final appearance cleaning and packaging. At the same time, key data during the production process (such as cell parameters, welding parameters, test results, etc.) are uploaded to the traceability system to realize the full life cycle traceability from raw materials to finished products, providing support for subsequent quality control and after-sales service.

Through the combination of automated equipment and refined management, the energy storage PACK production line can not only meet the needs of large-scale mass production but also ensure that each battery pack has efficient, safe, and durable energy storage performance, being widely used in scenarios such as home energy storage and industrial and commercial energy storage.

Equipment function

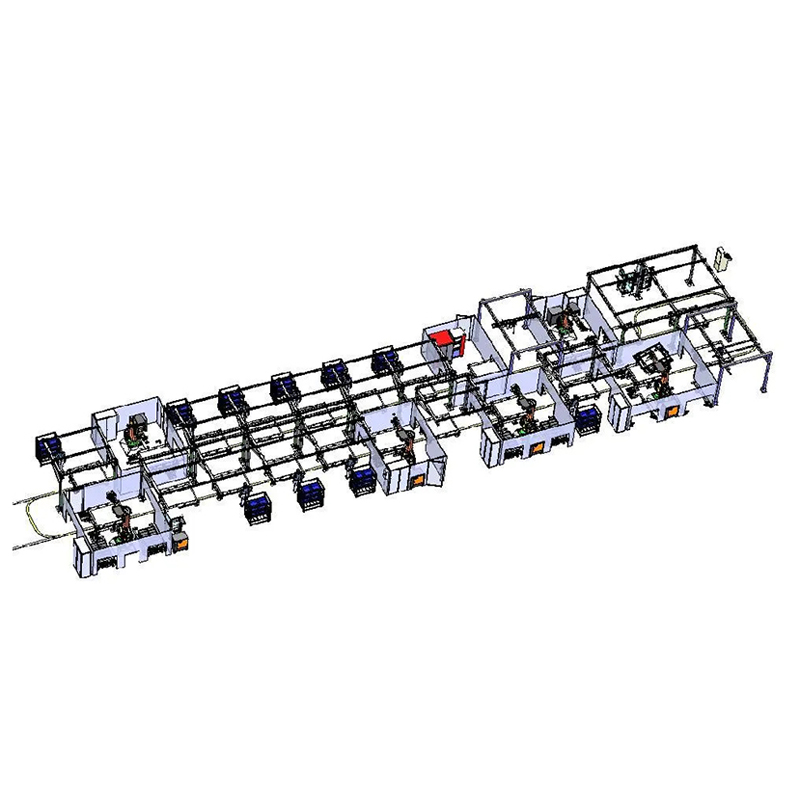

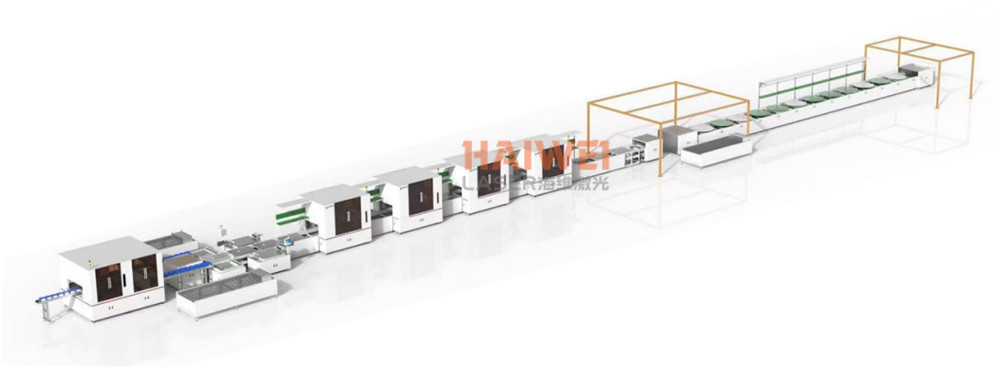

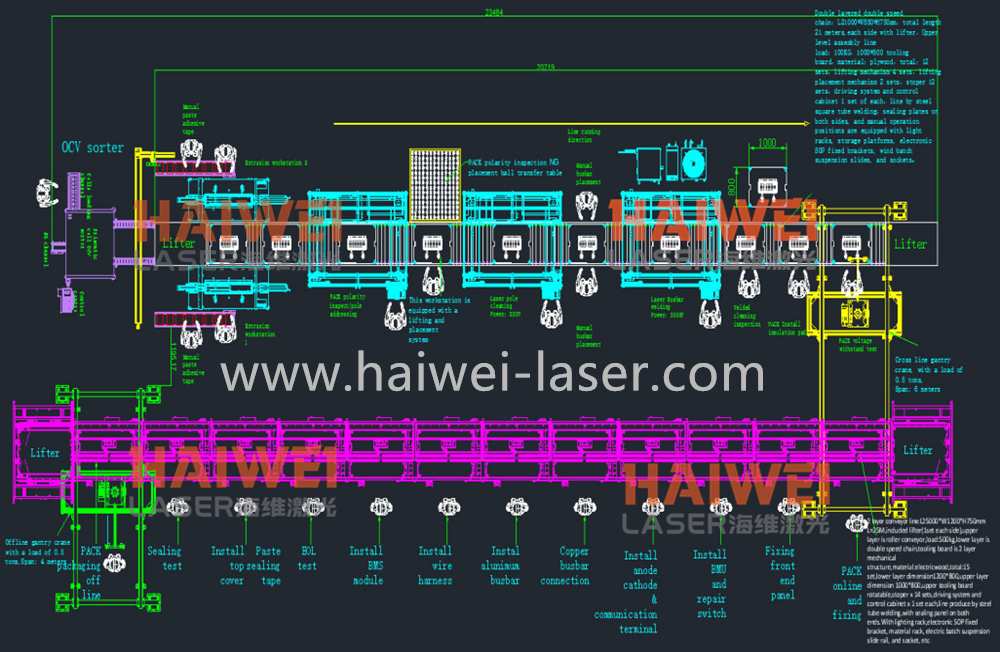

This customized production line is suitable for commercial ess & residential ess PACK;Used to complete the assembly, welding, testing, and assembly of air-cooled and liquid cooled PACK modules for prismatic energy storage cells,the production line includes: cells loading / cells code scanning / OCV testing / cells thickness measurement / auxiliary line of casing film paste / manual stacking in casing / automatic extrusion manual seel strip placement / manual scanning and code binding/automatic polarity detection / automatic pole cleaning / manual placement of busbar / laser automatic welding / welded manual inspection and cleaning / automatic total voltage internal resistance testing / gantry crane transfer line / manual PACK assembly line / gantry crane offline work station, etc.

Equipment advantage

█ High efficiency

The standard double speed chain module ensures the stability and quality of the product

█ Flexibility

It is compatible with more products of different requirements

█ Compatibility

It is compatible with a variety of prismatic lithium batteries and air cooling,liquid cooling process

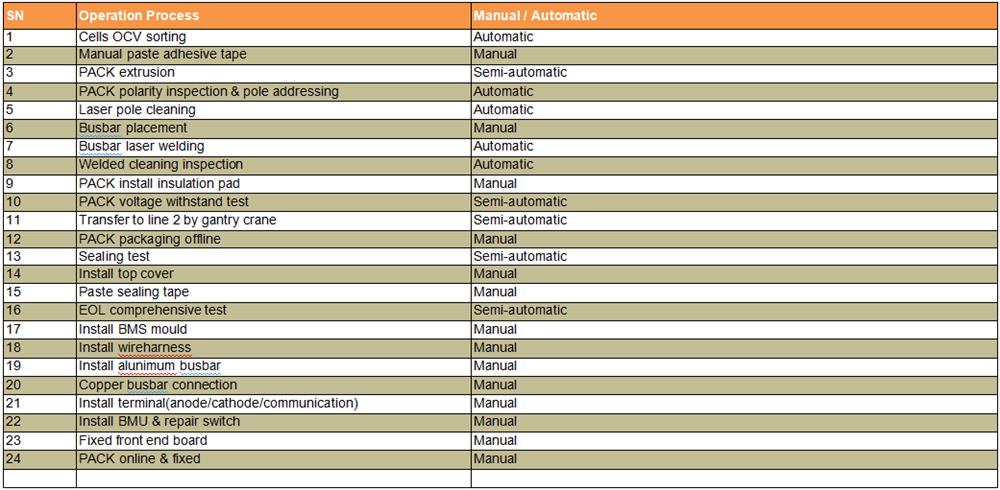

Ⅰ.PACK line workstation introduction:

(for reference only, upgrades such as adding equipment and improving automation can be made based on customer budget, personnel allocation, and production capacity requirements)

1.Cell OCV IR Sorting Work Station:

1.1 Size layout of battery cell sorting machine:

Prismatic OCV Battery Sorter

This equipment is a key device for performance screening of prismatic cells (such as prismatic lithium iron phosphate batteries, ternary lithium batteries, etc.). Its core function is to conduct accurate evaluation of the initial performance of cells through OCV (Open Circuit Voltage) detection combined with auxiliary parameters such as internal resistance testing.

In the energy storage PACK production line, the role of the prismatic OCV battery sorter is particularly important: it can eliminate cells with abnormal voltage, excessive internal resistance or poor consistency, and classify and group prismatic cells with similar performance parameters (such as voltage and internal resistance). This provides "homogeneous" cells for subsequent series-parallel assembly, thereby reducing problems such as attenuation of PACK cycle life, false capacity labeling or local overheating caused by cell differences.

The equipment usually has automatic feeding, detection, sorting and blanking functions, and is suitable for prismatic cell specifications of different sizes. It is widely used in the battery PACK production links in fields such as household energy storage and new energy vehicles, and is an important pre-equipment to ensure the safety and reliability of battery packs.

1.2 Process of battery cell sorting machine:

Main functions: manual cells loading online, code scanning, OCV testing, discharge NG cells

Cells feeding/discharging method:

Cells Loading(MANUAL)  OCV Auomatic Testing

OCV Auomatic Testing Cells

Cells

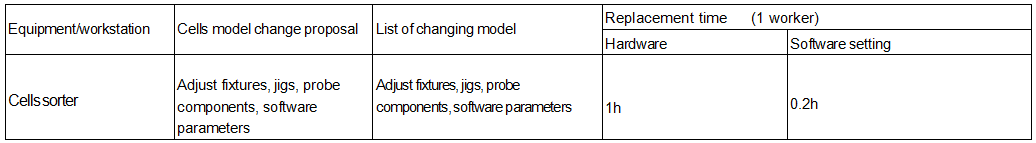

1.3 List of cells model replacement and required working hours for cells processing machines:

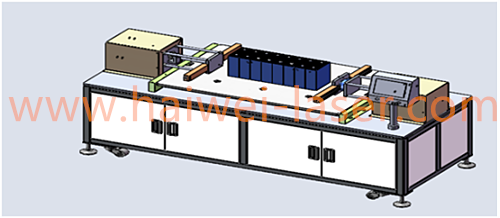

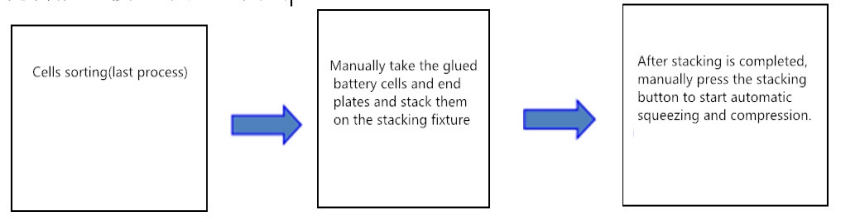

2. Semi automatic cells stacking extruder

Equipment dimensions(L x W x XX00mm X XX12mm X XX0mm (estimated dimensions, subject to actual dimensions)

3D schematic diagram of the equipment

Functions: module stacking, scanning code

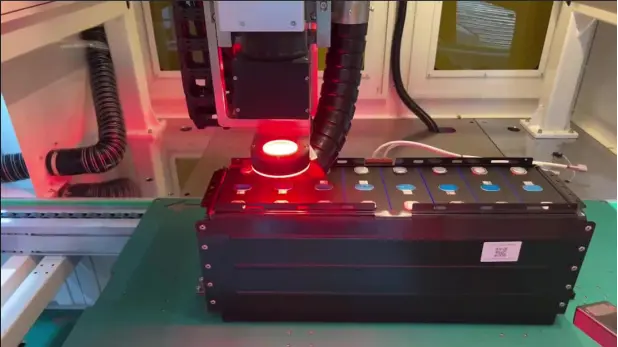

3 Polarity detection&laser cleaning machine

4 Busbar busbar laser welding machine

5.Electrode pole laser cleaning

In the process of battery module assembly, the pole, as an important component connecting the battery cell with other components, its surface cleanliness and conductivity are crucial. Laser cleaning can ensure that there are no contaminants on the surface of the pole, improve the electrical contact performance between the pole and components such as connectors, reduce resistance, and ensure the overall performance of the battery module is stable and reliable. At the same time, the surface roughness of the pole after cleaning increases, which is beneficial to enhance the mechanical bonding force between connected components and improve the structural stability of the battery module.

6.Busbar placement

7.Busbar laser welding

8.Welded cleaning inspection

9.PACK install insulation pad

10.PACK voltage insulation withstand test

11.Transfer to line 2 by gantry crane

13.Air tightness sealing test

14.Install top cover

16.EOL comprehensive test

17.BMS board installation

18.Install wireharness

19.CCS aluminum/copper busbar installation

20 Install terminal(anode/cathode/communication)

21 Install BMU & repair switch

- Tel:

-

Email:

Certifications

INQUIRY