How to Control Welding Parameters in Automatic Laser Welding Machines?

When investing in an automatic laser welding machine, understanding how to control the laser welding parameters is crucial for achieving high-quality welds. Proper parameter settings ensure consistency, efficiency, and minimal material distortion.

Understanding Key Parameters

The primary laser welding parameters include power, speed, focus position, and pulse frequency. Each of these must be finely tuned based on the material type, thickness, and desired weld characteristics. For instance, higher power levels are needed for thicker materials, while precise control over speed and focus ensures optimal penetration depth and width.

Material Considerations

Different metals have varying absorption rates and thermal conductivities, which directly affect the required settings. Stainless steel, aluminum, and copper each demand specific adjustments. Conducting preliminary tests with scrap material can help determine the best settings before full-scale production begins.

Real-Time Monitoring and Adjustment

Advanced automatic laser welding machines feature real-time monitoring systems that track the welding process. These systems can automatically adjust parameters during operation if deviations from set values occur, ensuring consistent weld quality throughout the batch.

Importance of Calibration

Regular calibration of the laser system is essential to maintain accuracy. Over time, components may wear or shift, affecting output. Scheduled maintenance checks and recalibration by qualified technicians guarantee that the equipment performs as expected.

Operator Training and Expertise

Even with automated systems, operator expertise plays a significant role. Staff should be trained on how to interpret weld quality indicators and understand when manual intervention is necessary. This includes recognizing signs of under or over-welding and making appropriate adjustments.

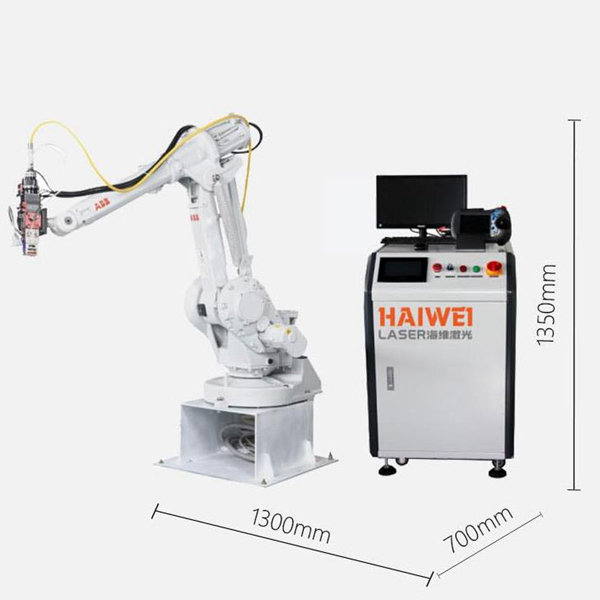

Controlling laser welding parameters in an automatic laser welding machine involves a combination of initial setup, continuous monitoring, regular maintenance, and skilled operation. By focusing on these areas, manufacturers can maximize their investment and produce superior welds consistently. Companies like Haiwei Laser provide not only state-of-the-art equipment but also comprehensive training and support services to ensure users get the most out of their machinery.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY