Does Laser Welding of Automotive Components Affect Fatigue Strength and Durability?

The use of laser welding machines in the automotive industry has grown significantly due to their precision, speed, and ability to handle various materials. However, a common concern among manufacturers is whether laser welding can impact the fatigue strength and durability of automotive parts.

Impact on Material Properties

When properly applied, laser welding can create high-quality joints with minimal heat-affected zones (HAZ), which helps maintain the original material properties. This is crucial for components subjected to cyclic loading where maintaining fatigue strength is essential. The localized heating by the laser ensures that surrounding areas remain unaffected, preserving the integrity of the part.

Joint Design Considerations

The design of the weld joint plays a critical role in determining the performance of laser-welded automotive components. Optimizing parameters such as weld penetration depth, bead shape, and joint geometry can enhance both the fatigue strength and durability. Engineers must consider these factors during the design phase to achieve optimal results.

Quality Control and Inspection

Implementing robust quality control measures is vital when using laser welding machines for automotive applications. Techniques like non-destructive testing (NDT) and real-time monitoring systems ensure that each weld meets the required standards. Consistent inspection protocols help prevent defects that could compromise the fatigue strength and durability of the component.

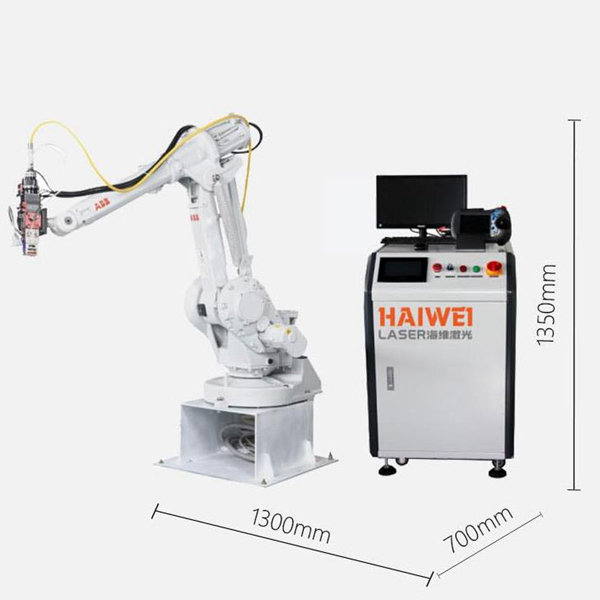

When correctly implemented, laser welding machines do not negatively affect the fatigue strength or durability of automotive components. Instead, they offer an efficient method for producing strong, reliable joints. Manufacturers should focus on proper weld design, precise parameter settings, and stringent quality assurance practices to fully leverage the benefits of laser welding technology. For those looking for dependable solutions tailored to automotive needs, selecting equipment from reputable suppliers who provide comprehensive support and expertise, such as Haiwei Laser, will be key to success.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY