Strategies for Optimizing Parameters on Laser Welding Machines

Optimizing the parameters of a laser welding machine is essential for achieving high-quality welds and maximizing efficiency. Understanding how to adjust these settings can significantly impact production outcomes.

1. Importance of Parameter Optimization

The performance of a laser welding machine hinges on correctly setting its parameters. Variables such as laser power, beam diameter, welding speed, and focus position directly influence weld quality. Precise parameter optimization ensures consistent results across different materials and thicknesses.

2. Key Parameters to Consider

Laser Power

Adjusting laser power is crucial for managing heat input. Higher powers are necessary for thicker materials or faster speeds, but too much power can lead to defects like spatter or burn-through.

Beam Diameter and Focus

The size of the laser beam and its focal point determine the energy density applied to the material. A smaller spot size increases energy concentration, beneficial for precision welding, while larger diameters spread the energy more evenly, suitable for broader joints.

Welding Speed

Balancing welding speed with laser power and beam diameter affects both productivity and weld integrity. Optimal speeds ensure thorough melting without overheating, reducing thermal distortion.

3. Practical Tips for Optimization

Conducting trial runs allows operators to fine-tune settings based on real-time feedback. Monitoring the weld pool's behavior provides insights into whether adjustments are needed. Additionally, using software tools that simulate welding processes can predict optimal parameters before physical testing.

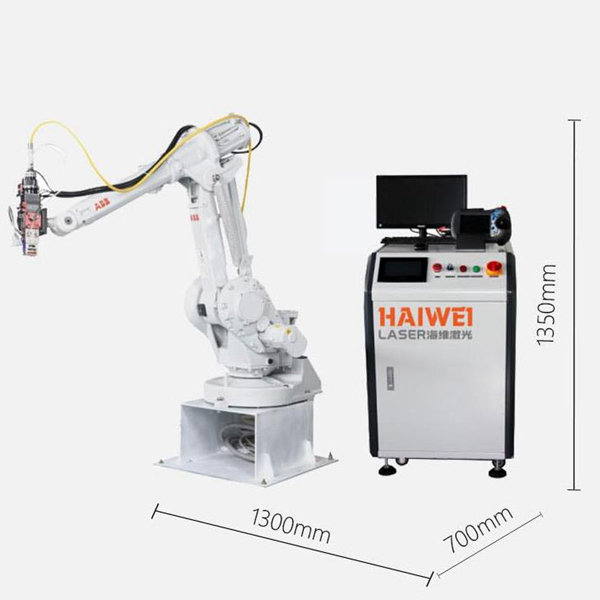

Effective parameter optimization on laser welding machines requires a thorough understanding of each variable's impact. By carefully adjusting settings and utilizing available technologies, users can achieve superior welds efficiently. For those seeking reliable solutions, Haiwei Laser, with 17 years in laser automation, offers advanced control systems and comprehensive support, ensuring your equipment operates at peak performance. This approach not only meets but exceeds expectations, providing users with the means to tackle even the most challenging welding tasks.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY