Advantages of Laser Welding Machines for Metal Tubing Applications

In the realm of metal fabrication, laser welding machines have become indispensable tools for achieving high-quality welds on metal tubing. Their precision and efficiency make them ideal for a variety of industries including new energy vehicles, advertising lighting, bathroom fixtures, and machinery manufacturing. Understanding these advantages can help potential buyers make informed decisions about investing in this technology.

1. Precision and Consistency

One of the most significant benefits of using a laser welding machine for metal tube welding is its ability to produce highly precise and consistent welds. The focused laser beam ensures minimal heat-affected zones (HAZ), which results in less distortion and superior mechanical properties compared to traditional welding methods.

Key Benefits:

Narrow weld seams with excellent repeatability.

Ability to handle complex geometries without compromising quality.

2. Speed and Efficiency

Laser welding is significantly faster than conventional techniques such as TIG or MIG welding. This speed advantage translates directly into increased productivity and lower operational costs.

Efficiency Tips:

Utilize automation features to streamline production workflows.

Optimize parameters for specific materials and thicknesses to maximize throughput.

3. Versatility Across Materials

A major selling point for metal tube laser welding is its compatibility with a wide range of metals, including stainless steel, aluminum, titanium, and copper alloys. Each material requires tailored settings but can be welded effectively with the right adjustments.

4. Reduced Post-Weld Processing

Due to the minimal HAZ and clean welds produced by laser welding, there is often little need for post-weld grinding or cleaning. This not only saves time but also reduces material waste and associated costs.

5. Enhanced Safety and Cleanliness

The non-contact nature of laser welding minimizes the risk of contamination and operator exposure to hazardous fumes. Additionally, enclosed systems provide an added layer of safety, making the workplace cleaner and safer.

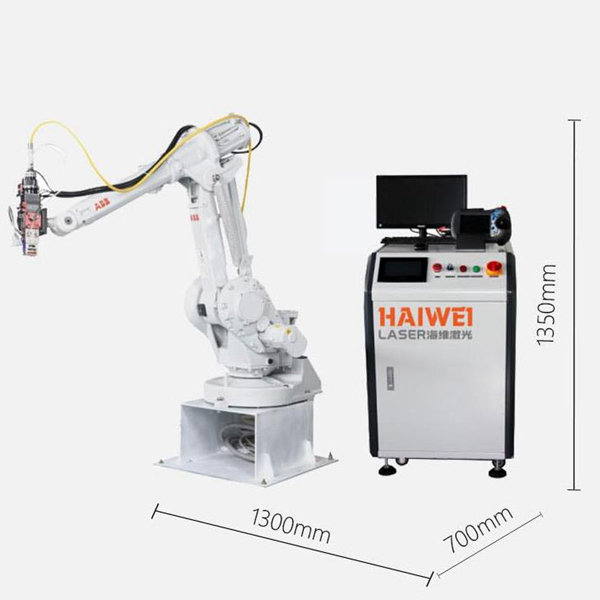

For businesses looking to improve their metal tubing welding processes, investing in a laser welding machine offers numerous advantages. From precision and speed to versatility and safety, these machines are designed to meet the demands of modern manufacturing while providing long-term cost savings. When selecting a laser system, consider your specific application needs and choose a supplier known for reliability and support — such as Haiwei Laser, which delivers high-performance solutions tailored for diverse industrial applications. This approach will ensure that you leverage the full potential of laser technology in your operations.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY