Enhancing Product Quality and Efficiency with Laser Welding Machines

In the fast-paced world of manufacturing, laser welding machines are becoming indispensable tools for improving both product quality and production efficiency. Understanding how these machines can benefit your operations is key to making an informed investment decision.

Precision Welding for Superior Quality

One of the standout features of laser welding machines is their ability to deliver high-precision welds. This precision minimizes distortion and ensures that joints are strong and clean. By focusing the laser beam on a very small area, heat input is minimized, which reduces thermal stress and warping in the material. As a result, products benefit from enhanced structural integrity and aesthetic appearance, contributing to overall product quality.

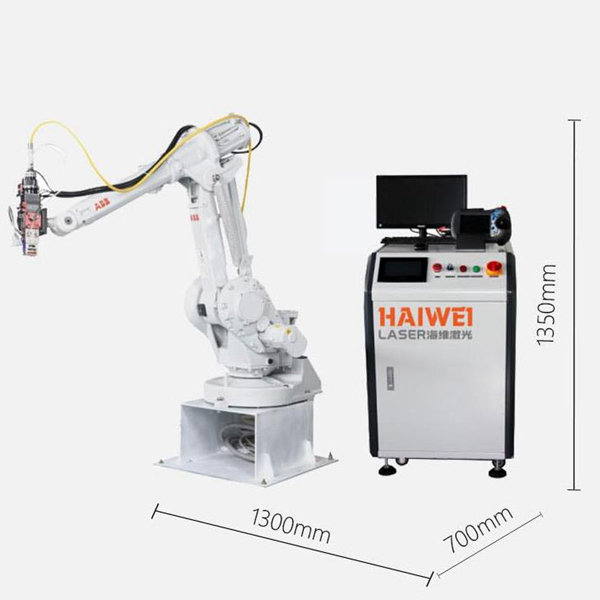

Automation for Increased Throughput

Automation capabilities in modern laser welding machines allow for continuous operation without human intervention. Automated systems can handle loading and unloading of parts, as well as monitoring the welding process. This not only speeds up production but also reduces the likelihood of errors caused by manual handling. Integrating such systems into your production line can significantly improve production efficiency and reduce labor costs.

Real-Time Monitoring and Quality Assurance

Advanced laser welding machines come equipped with real-time monitoring systems that track critical parameters like power output, beam focus, and temperature. These systems ensure that each weld meets predefined standards. Any deviations trigger immediate alerts, allowing operators to address issues promptly. This level of control contributes to consistent quality across batches and enhances customer satisfaction.

Customization for Versatility

The flexibility of laser welding machines allows them to be used across various materials and applications. Whether you're working with metals, plastics, or ceramics, there's a laser setup suitable for your needs. The ability to switch between different settings quickly means you can produce a diverse range of products efficiently. This versatility supports lean manufacturing practices and helps businesses stay competitive.

Energy Efficiency and Cost Savings

Modern laser welding machines are designed with energy efficiency in mind. They consume less power compared to traditional welding methods, translating to lower operational costs. Additionally, because they require minimal post-weld cleanup due to their precision, there's a reduction in material waste and secondary processing steps. Over time, these savings contribute to a better return on investment.

Investing in a laser welding machine can revolutionize your production processes by enhancing product quality and production efficiency. With their precision, automation capabilities, real-time monitoring, customization options, and energy efficiency, these machines offer significant advantages over conventional welding techniques. When choosing a system, consider your specific production needs and look for models that integrate seamlessly into your existing workflow. By doing so, you'll position your business for growth and success in today's competitive market.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY