Applications of Laser Welding Machines in Jewelry Making

In the world of jewelry manufacturing, precision and detail are paramount. The introduction of laser welding machines has revolutionized the industry by providing unparalleled accuracy and versatility. For those considering an investment in this technology, understanding its applications within the jewelry sector is crucial.

Precision Beyond Traditional Methods

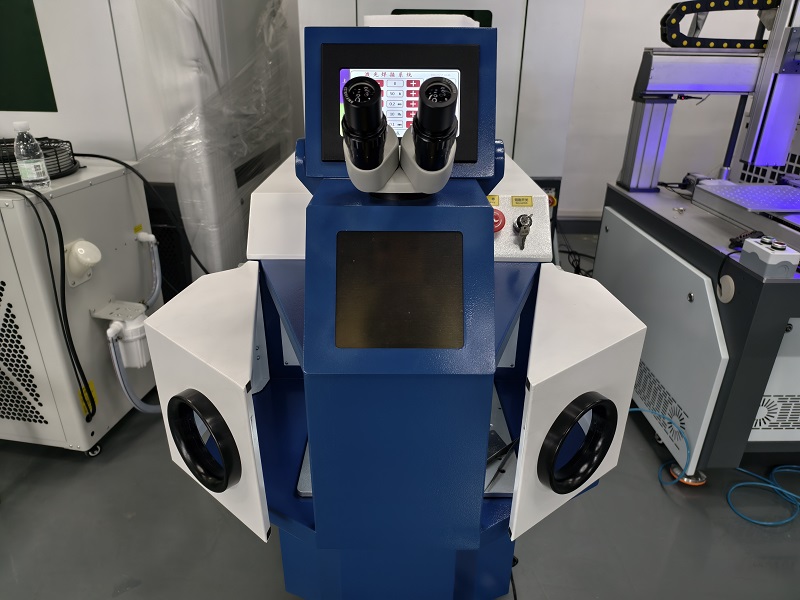

Traditional soldering techniques often struggle with intricate designs or delicate materials typical in high-end jewelry. Laser welding machines offer a solution by enabling welds that are both precise and clean, minimizing heat-affected zones and preserving the integrity of precious metals and stones. This makes them ideal for tasks such as repairing broken clasps, resizing rings, or attaching small components without risking damage to surrounding areas.

Customization and Flexibility

The ability to work with a variety of metals including gold, silver, platinum, and even titanium sets laser welding machines apart. Jewelers can now create custom pieces with complex geometries that would be challenging or impossible using conventional methods. The flexibility to adjust power settings allows for fine control over the depth and width of the weld, accommodating different thicknesses and types of metal.

Enhancing Efficiency and Productivity

Time is money in any business, and jewelry making is no exception. With faster setup times and the capability to perform multiple operations without changing tools, laser devices streamline workflows. Automated features like pre-programmed settings for common tasks reduce operator error and increase throughput. Moreover, the non-contact nature of laser processing eliminates the need for frequent tool changes and maintenance, further enhancing productivity.

Quality Assurance and Consistency

Consistency in quality is essential when producing luxury items. Laser processing ensures uniformity across batches by delivering repeatable results every time. Advanced systems come equipped with real-time monitoring capabilities, allowing operators to maintain strict quality control standards. This level of consistency not only meets but exceeds customer expectations, reinforcing brand reputation.

Environmental Considerations

Sustainability is becoming increasingly important in consumer markets. Unlike traditional welding processes, which may involve harmful chemicals or generate significant waste, laser welding machines operate cleanly. They produce minimal fumes and require less material for each weld, contributing to more environmentally friendly production practices.

For jewelers looking to stay competitive in a fast-evolving market, integrating laser welding machines into their workshops offers numerous advantages. From enhanced precision and customization to improved efficiency and environmental benefits, these machines represent a smart investment. When selecting a system, consider factors such as ease of use, available technical support, and scalability to ensure it aligns with your business needs. Investing in reliable laser equipment will not only meet current demands but also position your business for future growth.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY