How Long Do Laser Welding Machines Typically Last?

When investing in a laser welding machine, one of the most common questions from manufacturers is: How long will it last? While there’s no one-size-fits-all answer, several key factors influence the service life of these systems. Understanding them helps buyers make informed decisions and maximize return on investment.

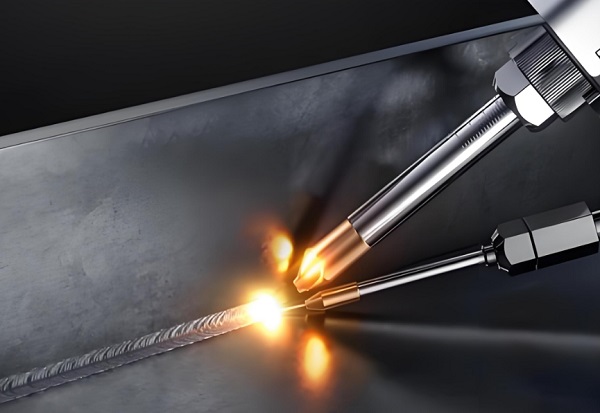

1. Type of Laser Technology

The core technology significantly affects longevity. Fiber lasers, for example, tend to have longer lifespans—often exceeding 100,000 operating hours—due to their solid-state design and fewer moving parts. In contrast, CO₂ lasers typically last around 20,000–40,000 hours, depending on maintenance and environmental conditions.

2. Usage Conditions and Workload

A machine running continuously at full power will naturally degrade faster than one used intermittently. High-duty-cycle environments, such as automotive or heavy industrial manufacturing, require machines built for sustained performance under stress.

3. Maintenance Practices

Regular preventive maintenance is critical. This includes cleaning optical components, checking cooling systems, and monitoring alignment. Manufacturers that follow recommended service schedules can often extend equipment life by years.

4. Build Quality and Brand Reputation

Well-engineered machines from reputable suppliers usually outlast cheaper alternatives. Look for systems with high-quality laser sources, durable motion components, and robust control systems.

5. Technological Obsolescence

Even if a machine remains mechanically sound, it may become outdated due to advancements in laser technology or automation capabilities. Some manufacturers upgrade older units with new control software or hybrid modules to keep them relevant.

Maximizing Your Investment

To get the most from your laser welding system:

Choose the right type for your application

Operate within recommended parameters

Follow maintenance guidelines

Partner with a supplier offering long-term support

In summary, a well-maintained fiber laser welding machine can serve reliably for 10+ years, while CO₂-based systems generally offer 5–8 years of service. With proper care and smart upgrades, your laser welding system can deliver consistent performance over its operational lifetime.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY