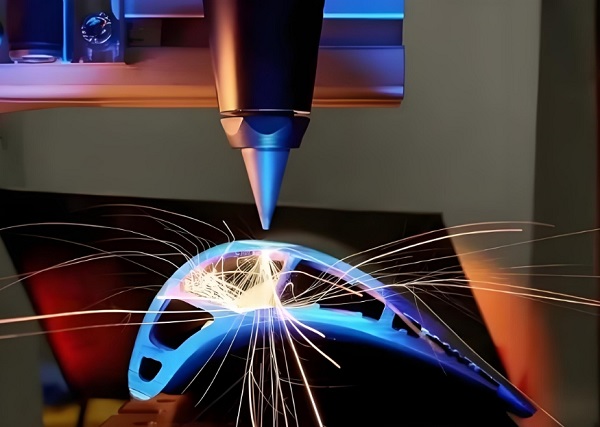

Key Considerations for Selecting a Laser Welding Machine

Choosing an appropriate laser welding machine is vital for ensuring welding quality and optimizing production efficiency. Whether in automotive, new energy, or medical device manufacturing, understanding these critical factors helps make a well-informed decision.

1. Material Type and Thickness

The primary consideration is the material to be welded—including steel, aluminum, copper, or other alloys—and its thickness. Different materials exhibit varying laser energy absorption rates. For instance, highly reflective metals like copper and aluminum often require higher-power lasers or specific wavelengths to achieve proper fusion.

2. Power Specifications and Output Consistency

Laser power directly influences weld penetration depth and processing speed. Machines typically range from 1 kW for thin sheets to over 6 kW for thick materials. Equally important is output stability; fluctuations can lead to inconsistent weld quality, particularly in precision applications.

3. Beam Quality and Focus Control

Beam quality (measured by the M² factor) determines the laser’s focusing capability. A lower M² value enables tighter focusing, resulting in deeper penetration and finer welds. This is crucial for micro-welding and high-precision industries such as electronics and medical devices.

4. Automation Integration Capabilities

Modern laser welding machines should support seamless integration with automation systems like robotic arms or CNC platforms. Prioritize models compatible with standard industrial protocols (e.g., Ethernet/IP, PROFINET) for easy system integration and future scalability.

5. Cooling System and Duty Cycle Performance

High-power laser welding generates substantial heat, making an efficient cooling system essential for maintaining consistent performance and extending component lifespan. Evaluate the machine’s duty cycle—the duration it can operate continuously without overheating—especially for high-volume production.

6. Software Features and Process Monitoring

Advanced software enables real-time parameter adjustment and process monitoring. Systems with sensor-based closed-loop feedback can automatically compensate for variations, enhancing weld consistency and reducing rework.

7. Total Cost of Ownership (TCO)

Beyond the initial purchase price, assess maintenance needs, energy consumption, and service support. Some systems may have lower upfront costs but higher long-term expenses due to frequent part replacements or high power consumption.

By thoroughly evaluating these factors, manufacturers can select a laser welding solution that aligns with current production demands while allowing flexibility for future applications.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY