Can Laser Welding Robots Deliver High-Precision Results?

Many manufacturers wonder whether a laser welding robot can truly meet the demands of high-precision applications—especially in industries like medical device manufacturing, electronics, or automotive powertrain components. The short answer is yes, but with important technical considerations.

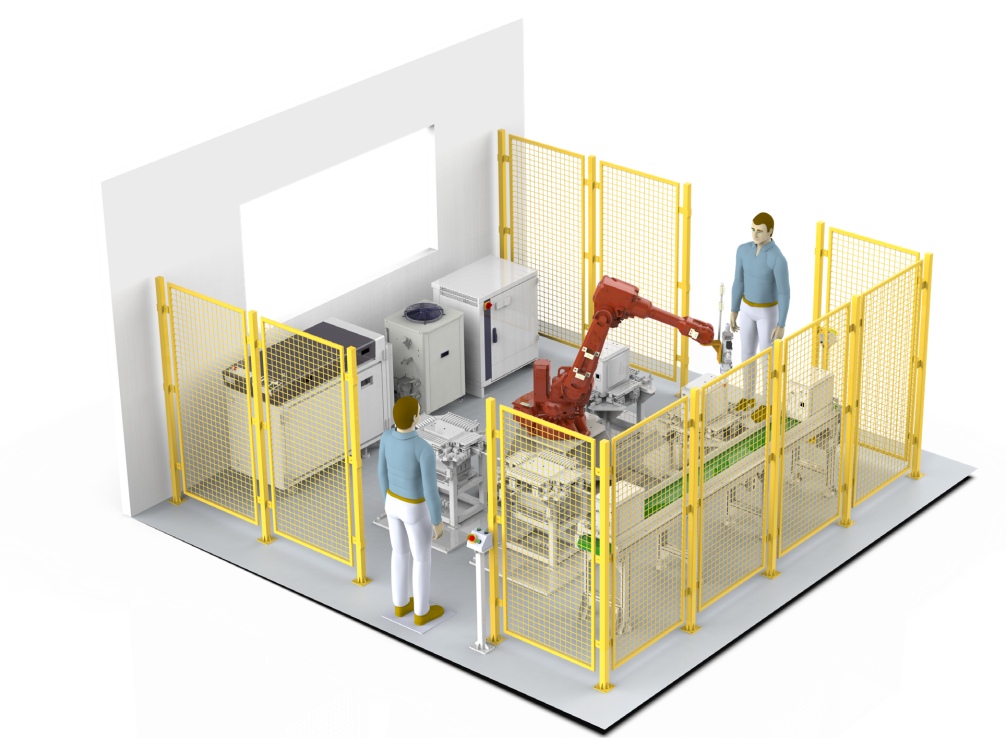

Precision Depends on System Integration

A laser welding robot isn’t just a robotic arm with a laser attached. True precision comes from the integration of motion control, laser parameters, and real-time monitoring. Modern six-axis robots equipped with high-resolution encoders and synchronized laser controllers can achieve repeatable weld placement within ±0.02 mm—sufficient for most micro-welding tasks.

Thermal Management Matters

High precision also means controlling heat input. Unlike traditional arc welding, laser welding delivers concentrated energy with minimal heat-affected zones. When paired with pulsed fiber lasers and closed-loop power control, a laser welding robot can consistently weld thin foils (as thin as 0.1 mm) without distortion or burn-through.

Vision and Calibration Enhance Accuracy

For complex geometries, integrating 3D vision systems allows the robot to locate joint seams dynamically. This compensates for minor part variations and ensures the laser stays precisely on target—critical when welding battery tabs or sensor housings where tolerances are tight.

Real-World Performance

In production environments, reliability matters as much as accuracy. Leading laser welding robots now feature predictive maintenance alerts and modular designs that simplify service. This reduces downtime and maintains consistent weld quality over thousands of cycles.

If your application requires repeatability, minimal post-processing, and compatibility with automated workflows, a well-configured laser welding robot is a practical solution. Focus on vendors who offer full system validation—not just hardware specs—and request weld samples under your actual production conditions before making a decision.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY