Laser Welding Robot vs. Gantry Laser Welding Machine: Which Is Better for Automation?

When planning an automated welding system, many manufacturers face a key decision: should they choose a laser welding robot or a gantry laser welding machine? Both have strengths—but the right choice depends on your production needs.

Flexibility vs. Precision

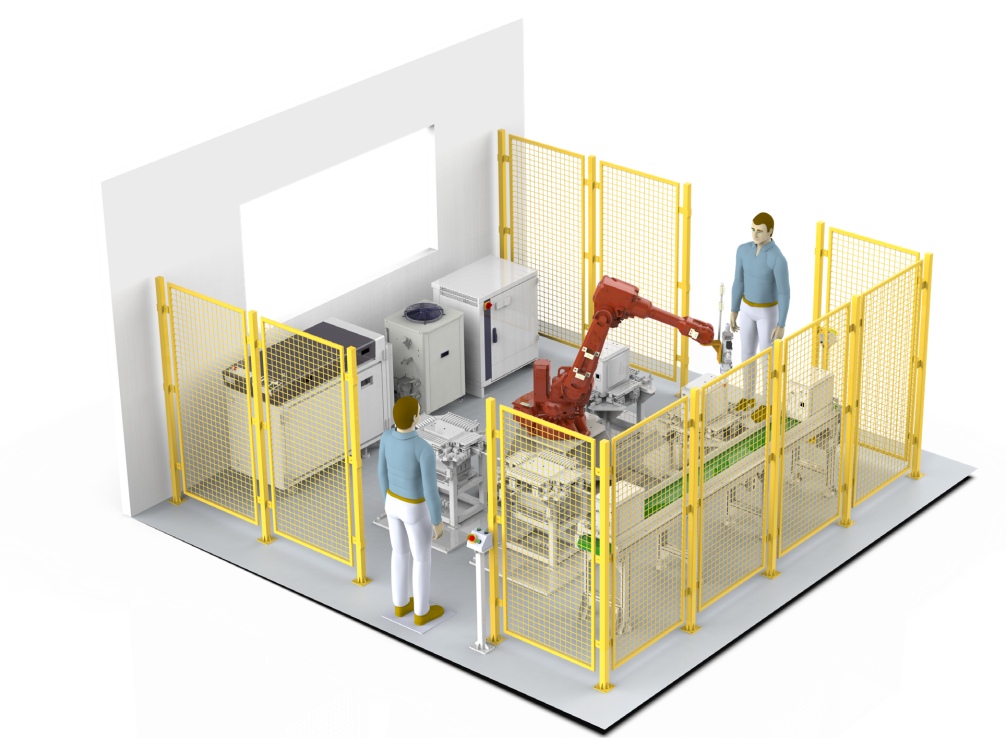

A laser welding robot excels in flexibility. Mounted with a fiber laser and integrated into a robotic arm, it can access complex 3D geometries—ideal for automotive body parts, battery modules, or custom fabrications. Programming is straightforward with modern offline software, and retooling for new jobs is relatively quick.

In contrast, a gantry laser welding machine uses a fixed optical path on an X-Y-Z frame. It offers superior repeatability and stability, especially for high-volume, flat or planar components like enclosures, trays, or sheet metal assemblies. With minimal moving mass in the optical head, vibration is reduced, leading to consistent seam quality at high speeds.

Throughput and Integration

For high-mix, low-to-medium volume production, the laser welding robot often integrates more easily with existing robotic cells and conveyors. However, if your application involves long, straight seams or requires micron-level positional accuracy over large areas (e.g., EV battery trays), a gantry laser welding machine typically delivers higher throughput with less calibration drift.

Final Consideration

Don’t base your decision only on upfront cost. Evaluate total cost of ownership—including maintenance, changeover time, and yield consistency. If your parts are mostly 2D or require extreme precision over large surfaces, go gantry. If you weld varied 3D parts and need agility, a laser welding robot is likely the better fit.

Both systems support Industry 4.0 when paired with proper controls—but matching the tool to the task matters most.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY