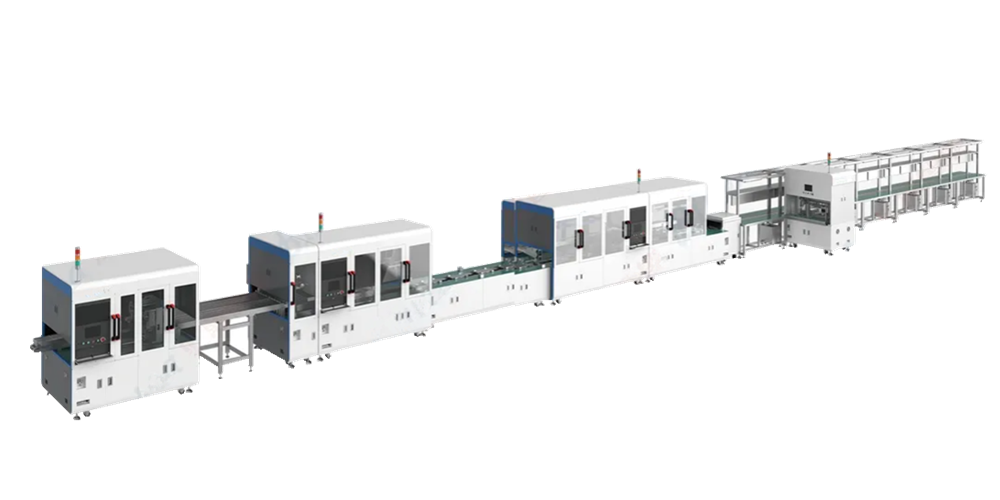

Lithium Battery Pack Production Line: Improving Quality and Production Efficiency

When investing in a lithium battery pack production line, the primary goals are consistent quality and stable throughput. For international buyers, especially those entering or scaling up in energy storage or electric mobility, understanding how to balance these factors is critical.

Focus on Process Integration, Not Just Speed

Many buyers prioritize cycle time, but true efficiency comes from seamless integration between processes. A well-designed lithium battery pack production line ensures smooth material flow from cell feeding to stacking, welding, testing, and final assembly. Minimizing manual handling and buffering reduces errors and bottlenecks, leading to more predictable output.

Quality Starts with In-Line Monitoring

High volume doesn’t have to mean compromised quality. The key is embedding inspection points directly into the production flow. Use vision systems for electrode alignment, automated leak testing after sealing, and in-process electrical checks before final packaging. This real-time feedback allows immediate correction, reducing scrap rates and rework.

Modularity Supports Flexibility and Maintenance

Choose a lithium battery pack production line with modular stations. This design allows for easier upgrades, faster changeovers between product variants, and isolated maintenance without stopping the entire line. It also simplifies training and spare parts management.

Data-Driven Performance Tracking

Modern production lines generate valuable data. Ensure your system logs key parameters—such as weld energy, insulation resistance, and torque values—for traceability. Connecting this data to a central dashboard helps identify trends, support root cause analysis, and maintain compliance with international standards.

Final Tip: Supplier Expertise Matters

Beyond hardware, evaluate the supplier’s experience in your target application. A partner familiar with regional safety regulations and production requirements can provide better long-term support.

In summary, an effective lithium battery pack production line combines intelligent layout, continuous monitoring, modularity, and data transparency to deliver both quality and efficiency over its operational life.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY