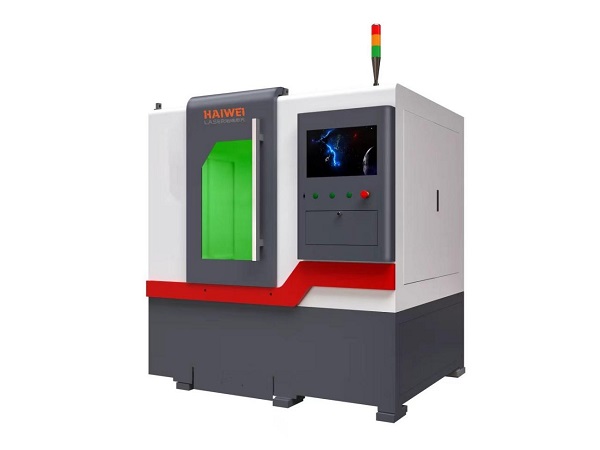

Laser Cutting Machine: Boosting Product Competitiveness Through Precision and Efficiency

In modern manufacturing, the ability to cut materials quickly and accurately can directly impact product quality and production costs. A well-chosen laser cutting machine enables businesses to achieve tighter tolerances, cleaner edges, and faster turnaround—giving them a measurable advantage in competitive markets.

High Precision for Complex Geometries

One of the main strengths of a laser cutting machine is its ability to produce intricate shapes with minimal deviation. With positioning accuracy typically within ±0.05mm, it’s ideal for industries like aerospace, automotive, and medical devices, where part consistency is critical. Unlike mechanical cutting, there’s no tool wear affecting edge quality over time.

Speed and Throughput Without Sacrificing Quality

Fiber-based laser cutting machines deliver high cutting speeds, especially on thin to medium-thickness metals (up to 20mm for steel). This allows manufacturers to meet tight delivery schedules while maintaining clean, burr-free edges—reducing or eliminating the need for secondary finishing operations.

Material Flexibility Across Applications

Modern systems handle a wide range of materials, including carbon steel, stainless steel, aluminum, brass, and copper. With proper parameter setup, a single laser cutting machine can switch between materials quickly, making it suitable for job shops or facilities with diverse product lines.

Integration with Automation for Unattended Operation

To maximize efficiency, many users pair the laser cutting machine with automated loading/unloading systems and nesting software. This reduces labor input and enables lights-out operation. Smart scheduling and real-time monitoring further improve machine utilization and reduce downtime.

Lower Cost per Part Over Time

While the initial investment may be higher than traditional methods, the long-term cost per part is often lower due to reduced scrap, less rework, and minimal maintenance. Energy-efficient fiber lasers also consume less power compared to older CO₂ models.

By improving accuracy, reducing processing time, and supporting flexible production, a laser cutting machine becomes more than just a tool—it’s a strategic asset for enhancing product quality and operational efficiency.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY