What Requirements Does a Laser Welding Machine Have for Operators?

In the field of laser automation equipment, laser welding machines have become indispensable tools for many enterprises. For users considering purchasing such equipment, understanding the operator requirements is crucial.

1. Basic Operational Knowledge

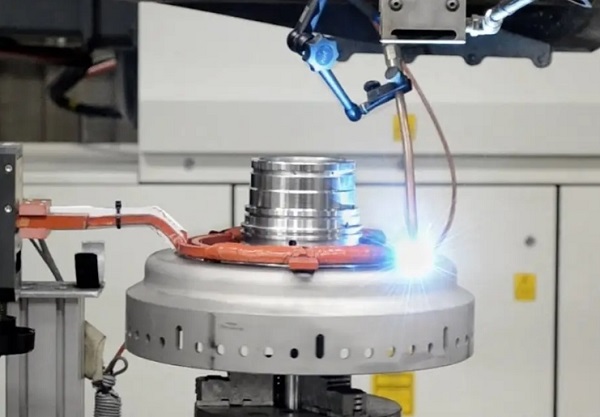

Modern laser welding machines are highly intelligent. Unlike traditional welding methods that demand extensive professional skills, these machines are designed for simplicity. Operators don't need to have years of welding experience. Even with zero - based knowledge, after a one - hour simple guidance, they can operate the machine skillfully. The intuitive user interfaces and automated functions make it easy to set parameters like power, pulse width, and welding speed. This means that as long as operators can follow basic instructions, they can start using the machine for welding tasks.

2. Safety Awareness

Although the operation is simple, safety can't be ignored. Operators should be aware of the potential hazards of laser radiation. They need to know how to use protective equipment such as safety goggles to shield their eyes from the laser beam. Also, understanding the emergency stop functions and safety protocols of the machine is essential. This knowledge ensures that operators can protect themselves and avoid accidents during the welding process.

3. No Need for a Welder’s License

One of the significant advantages is that operators don't need a traditional welder’s license. The intelligent design of laser welding machines has lowered the entry barrier. This is a great benefit for small and medium - sized enterprises or start - ups that may not have professional welders on staff. It allows a wider range of employees to be trained quickly to operate the equipment, reducing recruitment costs and expanding the pool of available operators.

4. Quality Control Awareness

Even with easy - to - operate machines, operators should have a basic understanding of quality control. They need to know how to check the welding results, such as the appearance of weld seams and the strength of welds. Some basic knowledge of the materials being welded (like metal properties) can help them adjust parameters if needed to ensure consistent and high - quality welding outputs.

In conclusion, laser welding machines are user - friendly for operators. With simple training, safety awareness, and basic quality control knowledge, even those without prior welding experience can operate them effectively. This not only meets the needs of enterprises for efficient production but also makes laser welding technology more accessible.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY