Laser Welding Robots: Greater Flexibility in Modern Manufacturing

In today’s advanced manufacturing environment, precision and adaptability are critical. The laser welding robot has become a key technology for industries seeking consistent, high-quality welds on complex parts.

Enhanced Motion Control for Complex Geometries

One of the main advantages of a laser welding robot is its superior flexibility. Integrated with 6-axis industrial robots, these systems can precisely direct the laser beam to hard-to-reach areas. Unlike fixed-beam setups, robotic arms adjust the welding angle and position dynamically, enabling seamless welds on curved, angled, or three-dimensional components—common in automotive, aerospace, and consumer electronics.

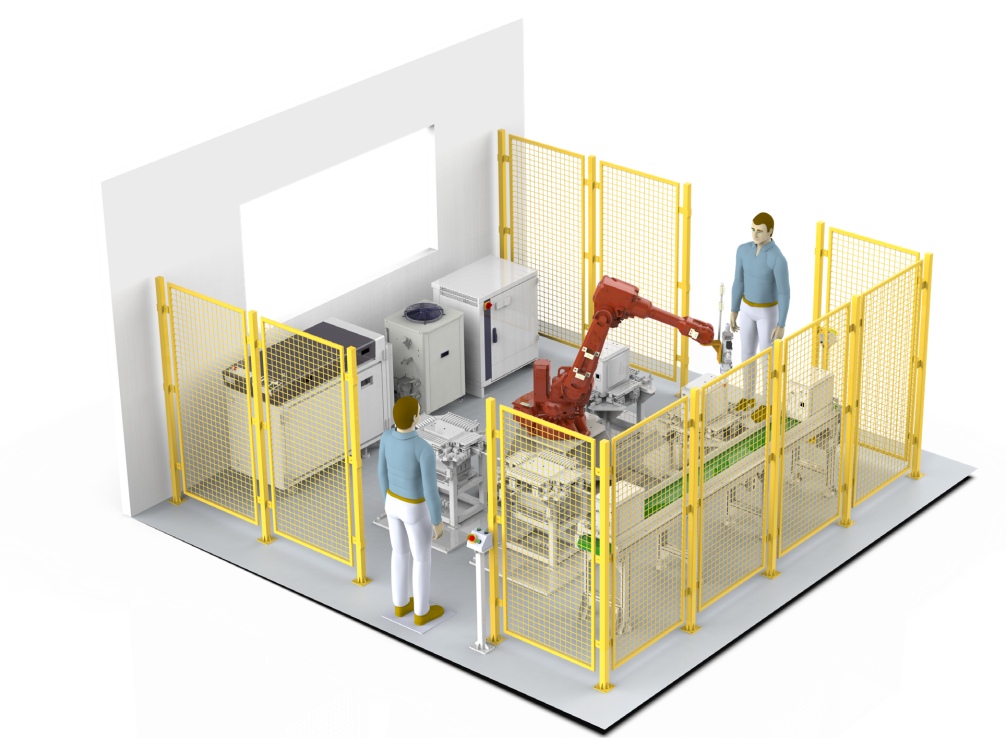

Seamless Integration with Production Lines

Modern laser welding robots are designed for easy integration into existing production environments. With support for common industrial communication protocols (such as Profinet, Ethernet/IP), they synchronize well with conveyors, part feeders, and quality inspection systems. This ensures smooth operation in both high-volume and mixed-product manufacturing settings.

Precision and Consistency in High-Demand Applications

Equipped with fiber lasers and real-time seam tracking sensors, these systems maintain weld quality even with minor part misalignments. The focused laser beam delivers low heat input, reducing distortion—especially important for thin-sheet metals and heat-sensitive materials.

Meeting Real-World Production Needs

For manufacturers facing frequent product changes or custom orders, the reprogrammability of a laser welding robot reduces changeover time significantly. Operators can store welding paths digitally and recall them as needed, improving repeatability and reducing setup errors.

Long-Term Reliability and Lower Operating Costs

These systems are built for durability, with minimal maintenance requirements. The combination of robotic automation and laser technology reduces reliance on highly skilled welders for routine tasks, helping companies address labor shortages while maintaining quality standards.

In summary, the laser welding robot offers a practical balance of flexibility, accuracy, and integration capability—making it a solid choice for evolving production demands.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY