Lithium Battery PACK Line: A Core Step in Modern Energy Storage Manufacturing

Understanding the Role of a Lithium Battery PACK Line

The lithium battery PACK line is where individual cells are assembled into functional battery packs for use in EVs, energy storage systems, and industrial equipment. It includes processes like cell sorting, stacking or module assembly, busbar welding, BMS integration, insulation testing, and final sealing. Unlike cell production, packing focuses on mechanical integration, electrical connection, and system-level safety.

Key Stages and Automation Needs

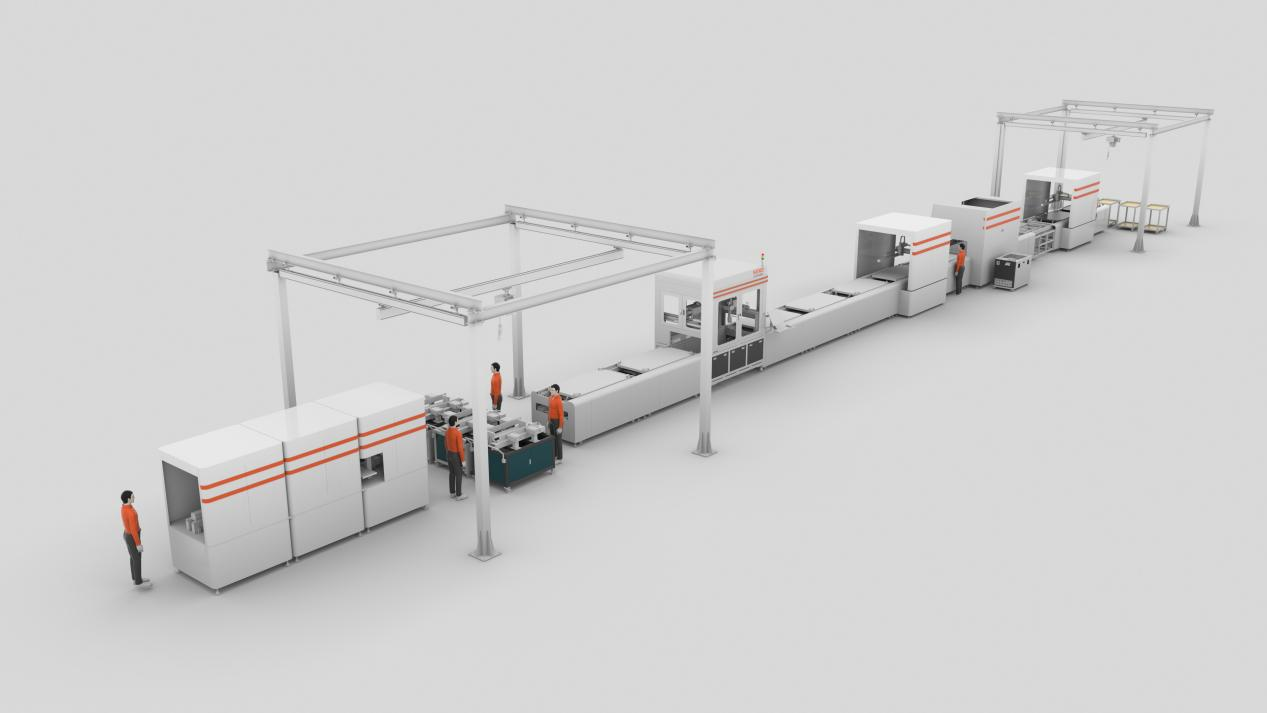

A standard lithium battery PACK line consists of multiple workstations: incoming inspection, cell feeding, laser welding, fastening, foam insertion, housing assembly, vacuum sealing, and final testing. High-volume manufacturers use robotic arms and conveyors to link these stages, ensuring consistent cycle times and traceability. For flexible production, modular designs allow quick changeover between different pack formats.

Quality Control and Process Reliability

Precision matters. Misaligned cells or weak welds can lead to thermal issues or early failure. Modern lines include inline vision systems for position verification, leak testing for enclosures, and electrical tests (IR, Hi-Pot) before shipping. Data from each step is often logged for full batch traceability, meeting automotive or energy industry standards.

Scalability and Cost Considerations

When selecting a lithium battery PACK line, buyers should balance automation level with budget. Fully automated lines suit large-scale operations, while semi-automated setups offer lower entry costs for startups or niche applications. Maintenance access, spare parts availability, and supplier support are also critical for long-term operation.

Integration with Factory Systems

Top-tier lithium battery PACK line solutions support communication with MES and SCADA platforms, enabling real-time monitoring and process optimization.

In short, a well-designed PACK line ensures performance, safety, and longevity of battery systems—making it a strategic investment in today’s energy landscape.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY