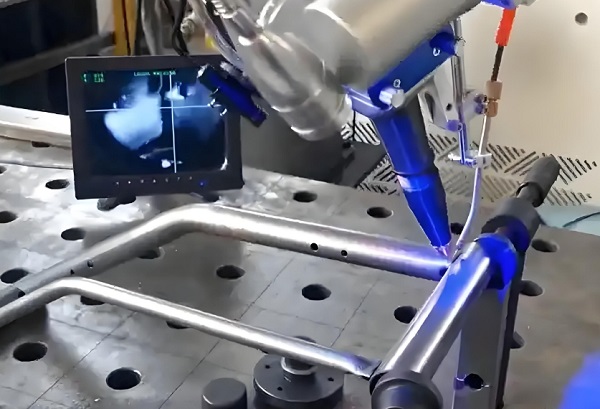

How to Perform Maintenance and Care for a Laser Welding Machine

A laser welding machine is a high-precision industrial tool that requires regular maintenance to ensure long-term reliability, consistent weld quality, and optimal performance. For businesses considering or already using laser welding systems, understanding proper maintenance procedures is essential for minimizing downtime and maximizing return on investment.

1. Regular Cleaning of Optical Components

The laser beam delivery system relies on mirrors and lenses that can easily become contaminated with dust, oil, or metal particles. Clean these components weekly using lint-free cloths and optical-grade alcohol. Avoid touching the surfaces directly to prevent scratches or coating damage.

2. Cooling System Inspection and Fluid Replacement

Most fiber laser welding machines use water cooling to regulate temperature. Check coolant levels regularly and replace according to manufacturer recommendations—typically every six months. Use deionized water or approved coolant to prevent mineral buildup in the heat exchanger.

3. Motion System Lubrication and Alignment

Linear guides, ball screws, and robotic joints should be lubricated monthly using manufacturer-approved grease. Misalignment or excessive friction can lead to positioning errors and reduced weld accuracy. Use precision measuring tools to verify alignment at least once every three months.

4. Electrical Connections and Power Supply Checks

Loose or corroded connections can lead to unstable output or component failure. Inspect all power cables, relays, and control boards quarterly. Ensure grounding is secure and check for signs of overheating or oxidation.

5. Software Updates and Parameter Calibration

Manufacturers often release firmware updates that improve system stability or add new features. Keep your control software up to date. Recalibrate weld parameters periodically, especially after changing materials or thicknesses, to maintain weld consistency.

6. Scheduled Professional Servicing

Even with regular in-house maintenance, it's recommended to have a qualified technician perform a full system inspection annually. This includes checking laser output power, recalibrating sensors, and replacing worn internal components.

By following a structured maintenance plan, users can extend the service life of their laser welding equipment while ensuring stable operation. Choosing a supplier with strong technical support and spare parts availability is crucial when purchasing a laser welding machine for industrial applications.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY