Unique Advantages of the Laser Welding Robot

Integrating a laser welding robot into a production line offers more than just automation—it delivers measurable improvements in precision, flexibility, and long-term operational efficiency.

Consistent High-Quality Welds

One of the main strengths of a laser welding robot is repeatability. Once a welding path and parameter set are programmed, the system can reproduce the same weld thousands of times with minimal variation. This level of consistency is difficult to achieve with manual welding and supports high first-pass yield, especially in regulated industries like automotive or medical device manufacturing.

Flexibility in Complex Geometries

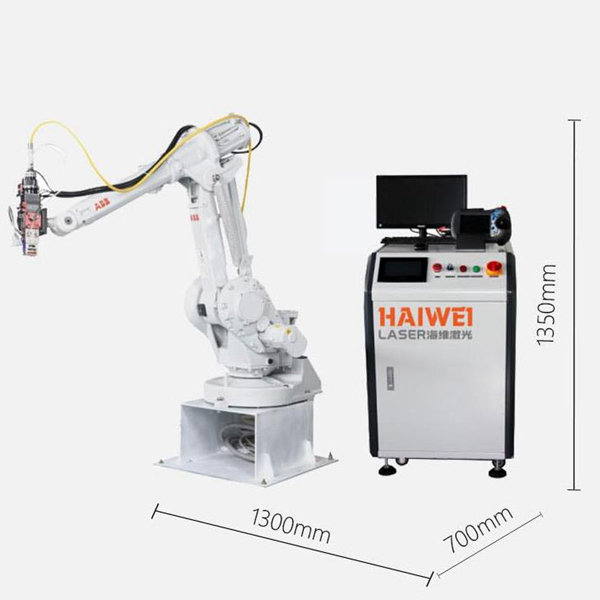

Robotic arms, typically 6-axis, can position the laser head at precise angles and reach tight or non-linear joints that fixed optics or manual tools struggle with. This makes the laser welding robot ideal for 3D components such as chassis parts, exhaust systems, or custom enclosures where joint accessibility varies.

Seamless Integration with Production Systems

Modern laser welding robots are designed to integrate with factory networks, PLCs, and vision systems. They can be linked to part tracking, quality control databases, and error-proofing systems. Some setups use camera guidance to correct for minor part misalignment in real time, reducing the need for precision fixtures.

Reduced Operator Dependency

While skilled welders are essential, their availability and consistency can be limiting factors. A laser welding robot reduces reliance on manual labor for repetitive tasks, freeing up personnel for supervision, maintenance, or higher-value work. Training for robot operators is often shorter than for certified manual welders.

Scalability and Long-Term Cost Efficiency

Once the initial setup is complete, scaling production is often a matter of duplicating programs or adding shift coverage. The robot can run unattended for extended periods, improving equipment utilization. Although the upfront investment is higher than manual systems, the total cost per weld typically decreases over time due to lower rework, material waste, and labor costs.

The laser welding robot stands out not just for speed, but for its ability to combine precision, adaptability, and process control. For manufacturers aiming to improve quality consistency and reduce long-term production costs, it is a practical investment. Focus on system integration, service support, and ease of programming when selecting a solution.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY