How to Choose Suitable Laser Equipment: A Practical Guide

Selecting the right laser equipment requires balancing technical needs and operational goals. Here’s a concise guide to help buyers make informed decisions.

1. Match Laser Type to Material & Application

Different materials demand specific lasers:

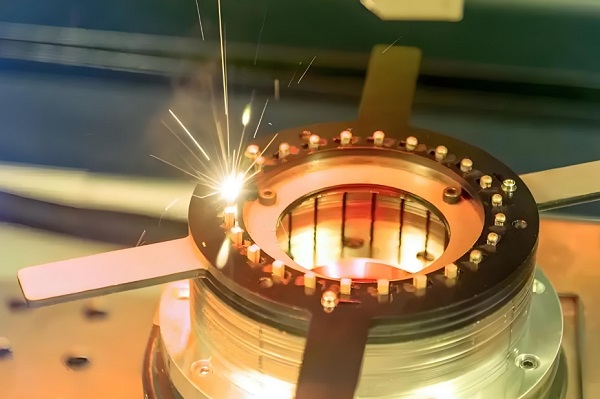

Fiber Lasers excel at cutting/welding metals (e.g., 1kW+ for steel sheets) due to high efficiency and low maintenance.

CO₂ Lasers suit non-metals like wood or plastics, ideal for engraving or cutting organic materials.

UV/Solid-State Lasers handle precision tasks on sensitive surfaces, such as marking electronics or medical devices.

Tip: Prioritize wavelength compatibility—1.06μm for metals, 10.6μm for non-metals, and shorter UV wavelengths for fine details.

2. Key Technical Specs to Prioritize

Power Output: Align with material thickness (e.g., 500W for 3mm aluminum, 2kW for 10mm steel).

Pulse Duration: Shorter pulses (nanoseconds/picoseconds) reduce heat damage, critical for fragile components.

Beam Quality (M²): Lower values (接近 1) ensure precise focusing, essential for high-accuracy applications like aerospace welding.

3. Evaluate Automation & Integration

Modern systems need seamless workflow integration:

Robotic Compatibility: Ensure compatibility with six-axis robots or conveyors via protocols like EtherCAT.

Vision Systems: 2D/3D cameras enhance accuracy by guiding lasers for complex geometries or irregular parts.

Software Flexibility: User-friendly CAD/CAM tools (e.g., LightBurn) enable quick program changes for diverse tasks.

4. Total Cost of Ownership (TCO)

Energy Use: Fiber lasers consume 30–50% less power than CO₂ models long-term.

Maintenance: Fiber lasers have minimal moving parts; CO₂ systems require periodic gas refills and lens replacements.

Support: Choose suppliers with 24/7 technical support and rapid spare parts delivery to minimize downtime.

5. Safety & Compliance

Standards: Ensure Class 1 enclosures and compliance with ANSI Z136 (US) or EN 60825 (EU).

Fume Extraction: Integrated systems reduce exposure to hazardous particles during metal processing.

6. Partner with Reliable Manufacturers

Experience: Opt for suppliers with proven track records in your industry (e.g., IPG for automotive, Gravotech for marking).

Customization: Seek providers offering tailored solutions, such as multi-laser hybrid systems for unique workflows.

Testing: Always request a demo with your materials to validate cut quality and throughput.

Final Considerations

Prioritize scalability—choose equipment that allows upgrades (e.g., higher power modules) for future needs. Avoid overcomplicating with unnecessary features or underinvesting in critical specs. By focusing on application fit, technical performance, and supplier reliability, you’ll secure a laser system that drives efficiency and ROI.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY