Does a Laser Welding Machine Offer Welding Process Visualization?

Yes, many modern laser welding machines include process visualization features, and this capability is becoming standard in industrial systems. Being able to see the welding process in real time helps operators monitor quality, diagnose issues, and improve consistency—especially in automated production environments.

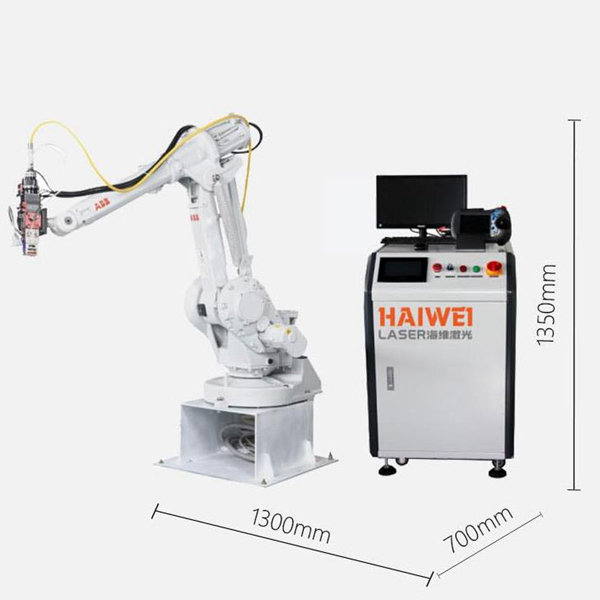

Built-in Camera Systems

Most laser welding machines designed for precision work come with integrated CCD or CMOS cameras. These are aligned coaxially with the laser beam, providing a clear view of the weld zone. The image is displayed on the machine’s HMI or connected PC, allowing users to observe part positioning, beam placement, and weld pool behavior during the process.

Why Visualization Matters

Visual feedback is especially useful when setting up new jobs or handling high-value components. Instead of relying solely on post-weld inspection, operators can detect misalignment, contamination, or shielding gas issues as they happen. This reduces scrap rates and improves first-pass yield.

Coaxial Imaging and Filtering

Since the laser emits bright light, standard cameras can’t capture usable images without special filtering. Advanced systems use optical filters and pulsed illumination to suppress glare and reveal details of the molten pool. This coaxial visualization method ensures the view stays aligned with the actual weld path, even on complex 3D parts.

Integration with Monitoring Software

In higher-end setups, the visualization system links with process monitoring software. Some systems record video of each weld for traceability, which is valuable in regulated industries like medical device or aerospace manufacturing. Others use image analysis to detect anomalies in real time.

Not All Systems Are Equal

While basic models may only offer a simple live view, more advanced laser welding machines provide zoom, image enhancement, and overlay functions (like crosshairs or weld path guides).

In summary, welding process visualization is a practical and increasingly common feature in laser welding machines. It adds transparency to the process, supports quality control, and helps users maintain consistent results across production runs.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY