Advantages of Using Laser Welding Machines for Large-Size Workpieces

Welding large components presents unique challenges in industrial manufacturing. Traditional methods often require multiple passes, extensive fixturing, and long cycle times. However, advances in laser technology have made laser welding machines a practical and efficient solution for handling large-size workpiece laser welding with improved precision and consistency.

High Precision Over Long Distances

One key benefit of using a laser welding machine for large parts is the ability to maintain tight tolerances across extended weld seams. With a focused laser beam, operators can achieve deep penetration and narrow welds, minimizing distortion. This is especially important when joining large structural components in shipbuilding, heavy machinery, or wind tower fabrication.

Reduced Part Distortion

Because laser welding delivers energy in a concentrated area, the heat-affected zone is smaller compared to arc welding. This means less thermal stress and warping—critical when working with large metal sheets or frames where dimensional stability is essential. Less post-weld correction saves time and reduces rework.

Integration with Motion Systems

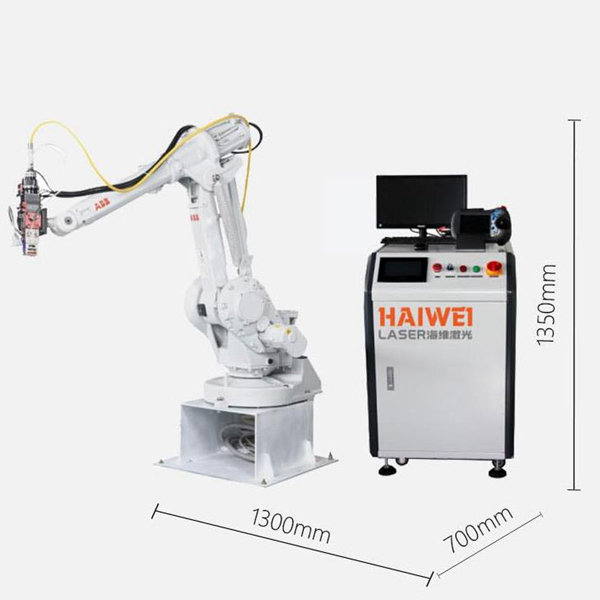

Modern laser welding machines can be integrated with gantry systems, robotic arms, or linear tracks to cover large work areas. This flexibility allows manufacturers to automate the entire welding process without moving the workpiece frequently. It also supports consistent weld quality from start to finish, even on multi-meter-long joints.

Improved Process Control

Laser welding systems often include real-time monitoring features such as seam tracking and adaptive focus control. These technologies help maintain weld integrity on large components that may have slight alignment variations or surface inconsistencies.

For companies considering this technology, it’s important to evaluate the workspace, part geometry, and production volume. Some systems are designed specifically for high-throughput environments, while others offer more flexibility for low-volume, high-mix production.

In summary, laser welding machines offer a reliable, scalable option for large-size workpiece laser welding. When properly configured, they support better accuracy, lower distortion, and higher automation levels—helping manufacturers improve quality and efficiency in large-scale fabrication.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY