Working Principle of a Laser Cutting Machine

For manufacturers evaluating advanced fabrication tools, understanding the working principles of a laser cutting machine is essential. These systems offer high precision and repeatability, but their performance depends on how well the underlying technology matches the application.

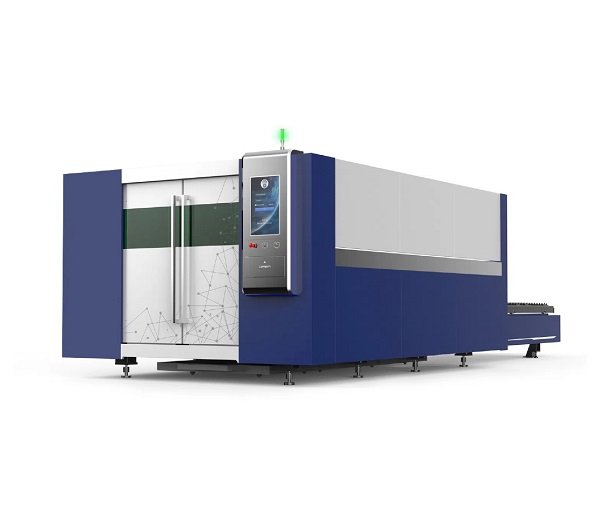

1. Basic Components and Setup

A typical laser cutting machine consists of a laser source (fiber, CO₂, or disk), a beam delivery system (mirrors or fiber), a focusing lens, a cutting head, and a motion control system. The laser generates a high-intensity beam that is directed and focused onto the material surface, creating a localized melt zone.

2. Material Interaction and Kerf Formation

When the concentrated beam hits the workpiece, the energy is absorbed, rapidly heating the material beyond its melting or vaporization point. An assist gas—oxygen, nitrogen, or compressed air—is blown coaxially through the nozzle to eject molten material and form a clean cut. The width of this cut, known as the kerf, depends on beam diameter, material thickness, and focus position.

3. Role of Wavelength and Power

Fiber lasers (around 1064 nm) are highly effective for cutting metals due to strong absorption, especially in steel, aluminum, and copper. CO₂ lasers (10.6 μm) are better suited for non-metals like acrylic or wood. Cutting speed and edge quality are influenced by laser power, pulse mode (continuous or pulsed), and beam quality.

4. Motion Control and Process Integration

Modern systems use CNC controllers to guide the cutting head or beam via galvo scanners. This allows precise path control for complex geometries. Integration with CAD/CAM software enables seamless transition from design to production.

For buyers, understanding these principles helps in selecting the right laser cutting machine for material type, thickness range, and production volume. Consider beam quality, assist gas requirements, and software compatibility to ensure long-term process stability and return on investment.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY