How Laser Automatic Welding Equipment Prevents Oxidation During the Welding Process

Oxidation during laser welding can compromise the integrity and appearance of the weld. Understanding how to prevent oxidation is crucial for industries relying on laser automatic welding equipment for high-quality, consistent results.

Use of Inert Shielding Gas

One of the most effective methods to prevent oxidation is the use of inert gases such as argon or helium. These gases create a protective atmosphere around the weld pool, displacing oxygen and preventing it from reacting with the molten metal. Proper gas flow rates are essential; too low may not provide adequate protection, while too high can cause turbulence and draw in air.

Optimized Welding Parameters

Adjusting key parameters like power density, welding speed, and focus spot size can minimize the heat-affected zone (HAZ), reducing exposure time to potential oxidation. High-speed welding with a focused beam minimizes the duration that the metal is at a temperature susceptible to oxidation.

Chamber Environment Control

For applications requiring the highest level of quality control, performing welding inside a sealed chamber filled with inert gas provides an environment virtually free of oxygen. This method is particularly useful for reactive metals like titanium and aluminum.

Post-Weld Cleaning and Passivation

After welding, any residual oxides can be removed through mechanical cleaning or chemical passivation. This step ensures that the surface remains corrosion-resistant and meets aesthetic standards.

Real-Time Monitoring Systems

Advanced laser automatic welding equipment often includes real-time monitoring systems that can detect changes in the weld pool indicative of oxidation. Such systems allow for immediate adjustments to parameters or gas flow to mitigate issues as they arise.

Proper Material Preparation

Ensuring that materials are clean and free from contaminants before welding reduces the likelihood of oxidation. Surfaces should be degreased and possibly pre-treated with anti-oxidation coatings if necessary.

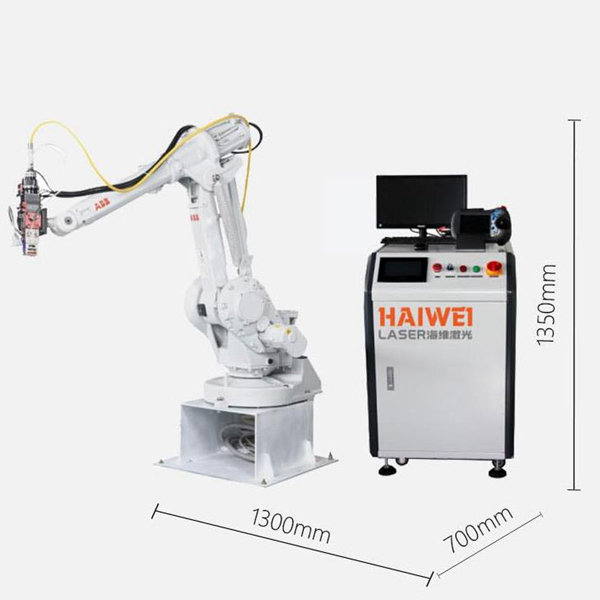

Preventing oxidation in laser automatic welding equipment involves a combination of proper shielding gas usage, optimized welding parameters, environmental controls, and post-weld treatment. By addressing these factors, manufacturers can achieve superior weld quality and consistency. Consulting with experienced suppliers like Haiwei Laser can offer tailored solutions based on specific production needs. For users looking to invest in laser welding technology, considering these aspects will ensure their equipment performs optimally and maintains the desired finish without oxidation defects.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY